Description

This product is protected by US Patent No. 11529663 and No. 11478838, and has other pending patent(s).

This package comes with everything you need to build nearly any cage or chassis component for any motorsport industry! Easily make accurate 25.5, 25.4, 25.3 or other drag or road race chassis, and also make SCORE-compliant off road roll cages and other recreational off road cages and components for vehicles like bouncers, crawlers, side-by-sides, and more. Complete welded m625 (xtreme heavy duty) tubing bender with all stickers already applied, and a fully assembled VersaNotcher or UltraNotcher. Comes with an indication gauge for bend angle and rotation of bend planes. Full color instructions and tech support included. Dies are on a 6 inch radius for the best bend quality and adherence to competition regulations, except 1 inch (where a 4.5 radius is plenty). See photos for full list of every component for each package. All clamp blocks are laser engraved for tube rotation. Non-mandrel applications include our new Thin Wall Roller (TWR) assembly for excellent bend quality on 1 5/8″, 1 3/4″ and 2″ diameter tube work. Our current lead times are based on order volume during Black Friday weekend, orders will ship in the order they are received.

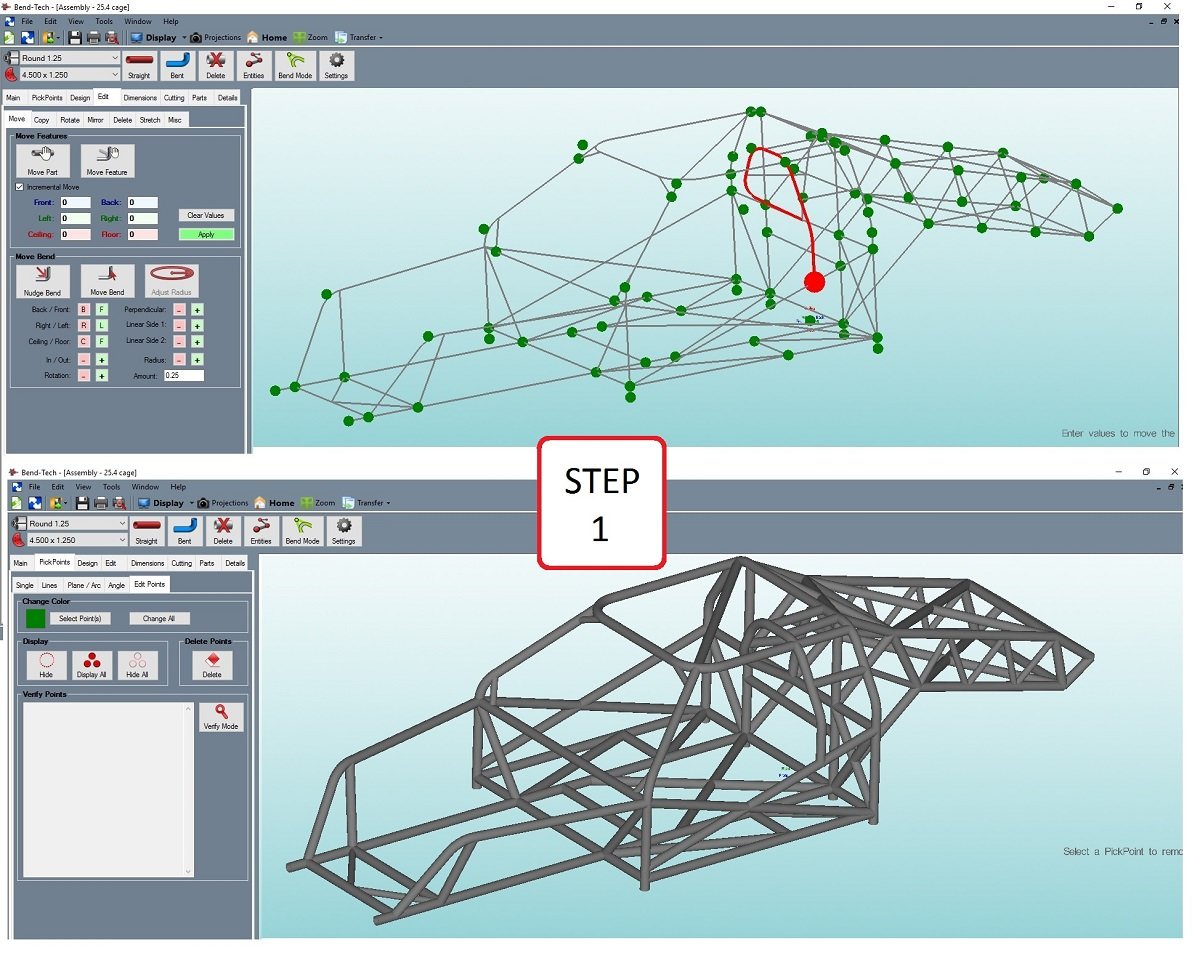

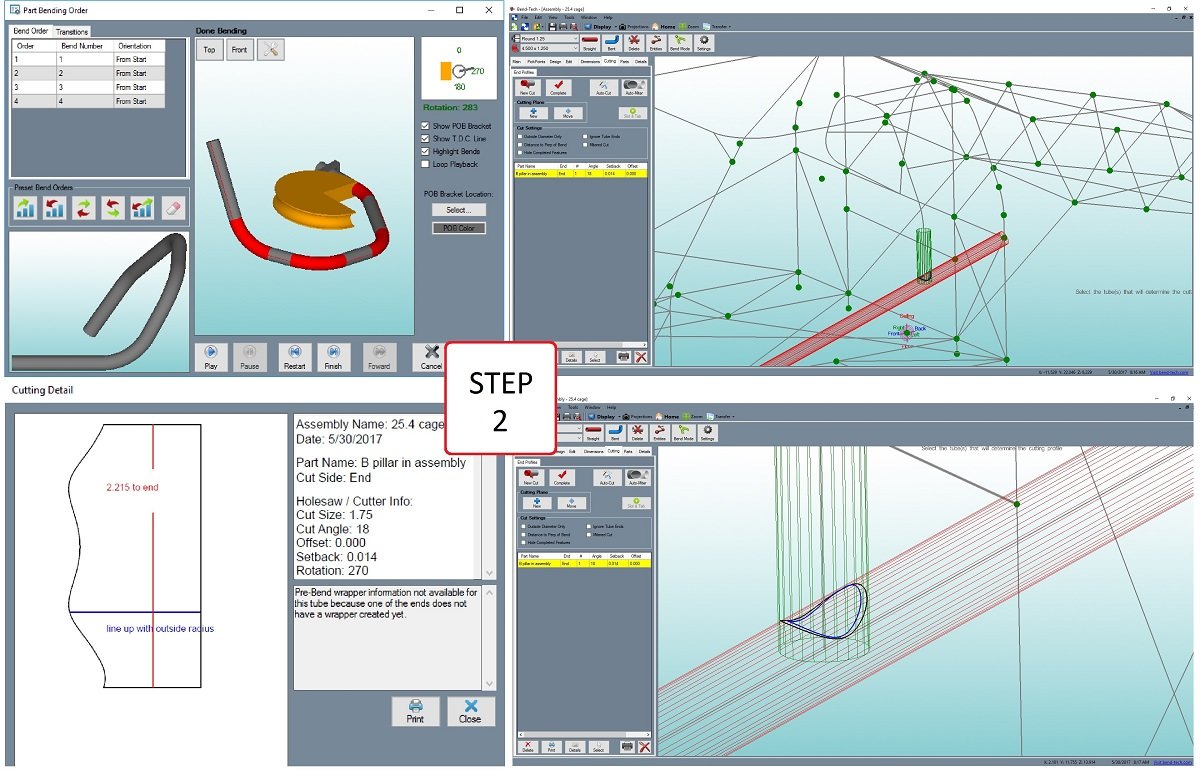

You do NOT need CAD experience or a high performance computer to run software such as Bend-Tech (sold seperately). You can watch 30 minutes of YouTube videos and build a complete chassis in the software in a number of hours, not days. The software will print out detailed instructions on how long to cut each piece, where to notch, how to bend them, and how much they will weigh. Each piece can be named, edited, copied, pasted, etc. Multiple tube sizes, scaling of parts or entire assemblies, no problem. The software has our machine and dies already loaded into a database. It will compensate for tube stretch, springback, and the variation between nominal bend radius and achieved bend radius (and you don’t need to understand these 3 terms, just run a calibration on the software, which includes bending a 90 and measuring it with a tape measure, and it will do it all automatically).

Machine hydraulic power requirements: The air/hydraulic option consumes 6 cubic feet of compressed air per minute (CFM) at 110 PSI, and requires no electricity at all. As long as your compressor has a storage tank, you don’t necessarily need 6+ CFM. Our other hydraulic systems are Electric/Hydraulic. The 1.5HP Elec/Hydro system draws ~8.1 amps at 220-250 volts AC. The 2.0 HP system draws ~12.5 amps at 220-250 volts AC. Our systems are designed for 60hz power (contact us for 50hz options if needed). They can also run on 208V power. We can wire our 2HP system for 110V at your request, but it pulls over 25A and is a highly unpopular configuration.

Machine Dimensions:

M6xx tubing bender: (assembled, ready to bend): 12”x30” floor footprint. Overall dimensions 12”x47”x32” (LxWxH). Weight 140-200 lbs.

M6xx Bender on Cart: 22”x34” floor footprint. Overall dimensions 22”x47”x68” (LxWxH). Weight 210+ lbs (depends on cart contents).

M6xx Mandrel Bender on Cart: 22”x34” floor footprint. Overall dimensions 22”x105”x68” (LxWxH). Weight 295+ lbs (depends on cart contents).

Photo Credits- (Orange Drift Car) Owned and raced by #MVKRacing, woman in photo @ThatOneEarthGoddess. (White BMW) Built for customer by Studio RSR.

Are you worried about learning how to bend tube? Or learning a new machine? Ours is the easiest to use, and able to make to most complicated bends. Let us show you in under 7 minutes:

Want to see a whole project from start to finish, and even more bending tricks that are 100% unique to our design? Watch this video:

How hard is it to change dies? Super easy! Here is a video of a die set change;

Have you ever seen a tubing bender bend 2.00″ Solid steel bar at room temperature? Now you can!

Please see our wall thickness capacity chart for full details. It is in our tech section on our web page.

Please read our terms and FAQ for complete information about warranty, returns, and more.

6 reviews for Ultra Motorsports Package NHRA/SFI/SCORE, 4×4, SXS**