A Roguefab tubing bender can easily manipulate metals for

industrial and

commercial purposes like:

-

- stainless steel (including sanitary and architectural)

- carbon steel

- aluminum

- copper (hard and soft)

- brass

- titanium

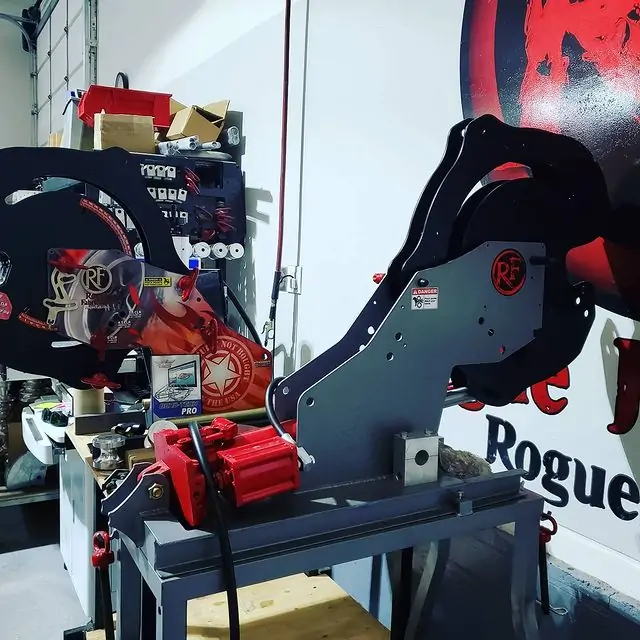

Why RogueFab hydraulic tubing benders are the most sensible choice?

Our broad range of high-quality electric tube benders is assembled and sold in the United States, following elite engineering standards. We utilize premium US-made billet aircraft-grade 6061-T6 to machine our dies and US-milled P&O steel (cut on a fiber laser) for our high precision tools and instruments.

The M600 model is the ONLY tubing bender that makes true S bends (bends touching, back to back in opposite directions). Applications include offset door bars and more. See our tech section for more info.

Every M600 bender can be converted into a true mandrel bender (in minutes). This makes the Mandrel M600 the

most affordable mandrel bender in the world by a factor of about 10X (competitors start above $30K).

With an isolated clamping system, the M600 is the easiest machine to learn to bend tubing on. You can remove your bends from the machine, measure them (on a vehicle if needed), and put them back in for more bend angle with just one pin. There is no easier system for building one-off projects.

All HD and xHD models bend 94 degrees in one ram stoke. After 3 strokes, you are beyond 180 degrees. Spend less time adjusting your machine, and more time fabricating!

We have bent 2" diameter solid steel bar in the M600 xHD (on video, too). It has a full machine lifetime warranty bending 2.00 x .250 wall DOM tubing. No other machine can hold up to that abuse at anywhere near the low price of an M600 model.

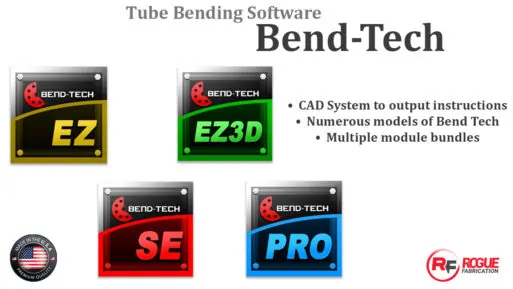

We share and teach you more than any other tool manufacturer. Our technical index contains free design guides, tube and pipe calculators, and project videos. We explain how tube benders work, show you why ours can bend titanium and thin stainless, and simplify the pipe bending process with our free calculators and machine specific calculators, and capacity charts.

Check how Roguefab benders compare to all the

best tube benders on the market.

Instagram Feed

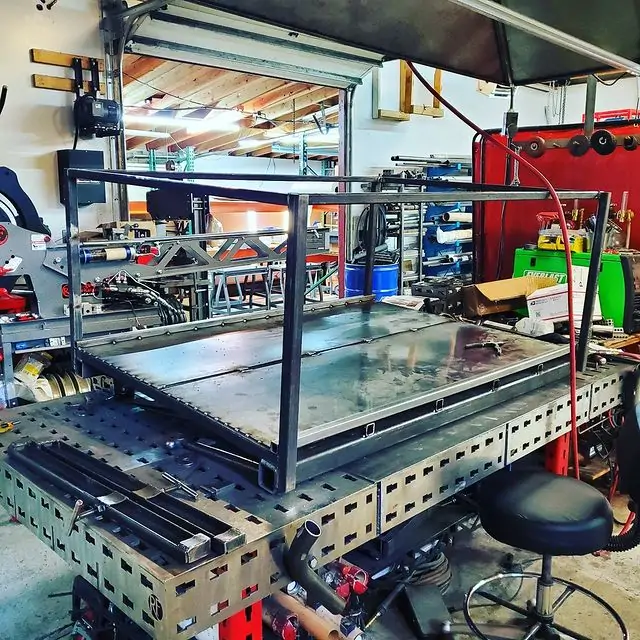

What can you do with our tube bender tools?

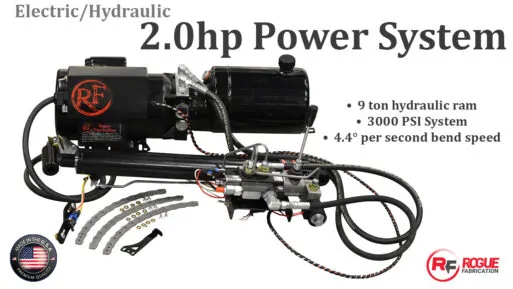

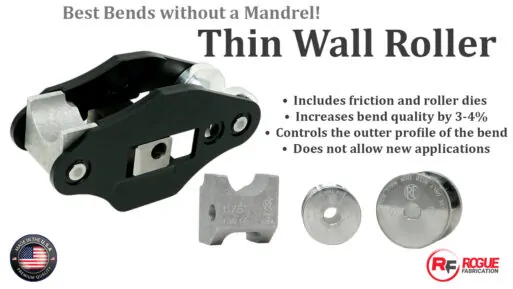

RogueFab's "upgrade as you go" approach offers great flexibility in customizing the perfect tube bender product that fulfills your needs and surpasses your expectations. You can start with an affordable pipe bender kit, and add on automation and performance increasing features as your shop or company needs them.

You can

use the tube benders for a huge variety of metal fabrication projects including:

Building roll cages, bumpers, rock sliders, suspension components

Complete chassis (NHRA/SCCA/NASA/SFI/SCORE/Formula D/FD/Lemons/FIA)

Mandrel pipe and tube bender

Non mandrel pipe bender / tube bender

Handrails

Thin and thick wall tubing

Furniture and gates

Trailer frames (including square tubing)

Refinery and brewery pipes (including Rathgibson 316L and Sandvik 2507 Duplex Stainless)

Inconel

DOM tube bending

Chromoly bending (4130N and comparable mild Docol R8)

Bending automotive steel and titanium exhausts

Exceptional customer service

Accuracy, affordability and accessibility are what we aim for in every interaction with our customers. We offer blazing fast lead times for sourcing our tube/pipe benders and offer a large free technical index.

Feel free to call us at

503-389-5413.