Tubing Bender Reviews

This collection of reviews if from our old system – before reviews could be posted right on the products where you buy them. For a full range of product-specific reviews, just click on “Products” at the top of any page, and shop like normal. The reviews are easy to find, just like on Amazon or anytwhere else. The reviews and descriptions that compare the RogueFab Tube Benders to JD2, ProTools, Beileigh, and others here are not found anywhere else, so they warrant reading.

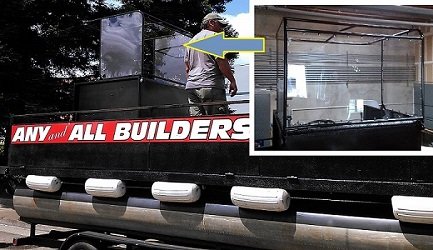

From Chris at IDF (Innovate-Design-Fabricate) in Rancho Cordova, CA

“I wanted to thank you again for all of your support; your bender has been awesome. I have attached the photos of the Stainless tubing to help you out. It bent just fine and I will send more pics of the completed project. I have also sent photos of our other completed projects your bender has done for me. Feel free to share them understanding we did the fab with your product and we are a thankful team here at IDF!”

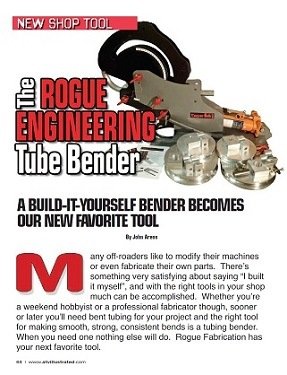

ATV & side-by-side Illustrated wrote a 4 page article about our tubing bender that was published in their April 2013 Issue. Click on the picture of the article to see the full 4 page article in full size!

From Matt in Southern IN

This twin turbo 5.8L Ford powered Ultra4 racecar is being built by Matt in Southern Indiana. He started with the chassis, but has rebuilt half of it with a RogueFab tubing bender!

“Having used manual benders and this bender….here is what I feel are the pros of the Rogue Fab bender:1) Cheap cost for a air/hydraulic bender that a shady tree fabricator can afford (everytime the air piston cycles I think of all of the effort I spent hanging onto a breaker bar and how I was dead tired by the end of the day and then smile ) 2) Consistent bends (watching the indicator and having control of the air). You’re not yanking on a breaker bar…especially yanking on a breaker bar and watching the angle readout at the same time… 3) It’s super portable. I have it sitting (does not need to be bolted down) to my rolling fab table with my tube notcher and vise. Everything is right there…where I am working. I don’t have to mount the bender to my concrete floor, trailer flooring, or anything else. Picture – I bought this chassis used for a trail rig…then decided I wanted to race U4. To be what I wanted, I literally have redone 1/2 of the tube work. My bender worked flawlessly and the dies do not show any wear.”

All these awesome custom side-by-side cages were built by a fabrication company that bought our bender for their shop.

”Been really impressed with the bender. Great customer service as well. Done a few things with it so far.”

This built narrowed 1973 Bronco was built by Jason in WA, and he said…

“I was skeptical to buy a bender from a new company, but I wanted an alternative to the pro-tools and JD2 benders out there. I scoured the internet looking at every review and debate on the machine and couldn’t find a reason not to try it, so I ordered one up. I couldn’t be happier. This machine is fun to use and produces great bends. I am building a cage for my 73 bronco to keep myself and my family safe after a near death endo (my last cage got destroyed and I came out luckily not hurt). I decided to build it right and tie it into my frame and not sheetmetal and use DOM instead of cheap tube (what I had). Just started my build and couldn’t be happier with the bender. Things I love about it, 1: block clamps pipe while bending, then I can pull it out and if not bent far enough I can slide it right back in without aligning anything to bend further if needed. 2: I can keep it on a cart and wheel it around my garage. 3: I can throw it in my truck easily to take to a friend’s house. 4: it bends vertically and not horizontally (don’t need a lot of floor space). 5: Made in Portland, OR USA! Best bender on the market for the price that I could find! Thx a lot Joe for such a great product, I sell it to everyone that asks about it…lol!”

Garrett from Lake Elsinore, CA, posted this review on NAXJA.org. He bought our bender to rebuild his Jeep XJ Cherokee after a serious rollover compromised the body.

“Let me start by saying I am posting this thread up for anyone that Is in the market for a new tube bender. This is my experience, as a rookie, novice, and self-taught builder. I have no ties to the said manufacturer of this product. I paid full price for it, didn’t get any kickbacks or free stuff. I just want to give other people, like myself, a chance to see how this product performs.I recently purchased a Rogue fab tube bender to aid in the cage construction for my current build. This is my first real tube bender, and really my first attempt at building a roll cage. I have used a cheapo HF crush bender, in the past, to build a bumper and tire carrier, but this is a whole other animal. I decided to go with their most affordable set up, the 1.75″, 4.5″ CLR, 180′ bender/die set. I feel bad for the delivery guy that had to carry this to my door step, as this is a 100lb package deal in one box. The bender comes unassembled and has to be welded together. The instructions were very simple to follow, and all the pieces really fit together quite well. The only item I had to go out and purchase was an air/hydro ram that I picked up from harbor freight for about $60 after all my discounts. It took about 2 hours for me to assemble and weld everything together. I still have yet to paint it, but I wanted to make sure I knew how to operate it before I get it all painted up. I did find that the hitch pins they send with the kit have a VERY TIGHT fit. Only one of the pins really get pulled on a regular basis, so I just lubed the others and worked them in. Maybe a little clearancing in these locations would help them fit a little better. (Note from Rogue Fab not part of this review: We’re increasing the hole size just a little to allow for pin size variance.) The fully assembled unit is VERY heavy. I am tempted to mount some small casters under it to make it easier to move around the garage. If I had a tall shop, I would mount it to a mobile bench for sure. The unit seems to be very well balanced, it doesn’t even budge with a 10′ section of pipe hanging off the side of it, so I do t think it would have any issues sitting on a bench.

I have really liked working with this bender, it’s a great product”

Recently posted on a public forum (Pirate4x4) by Jimmy in Poolville, TX

“I recently purchased this bender after EXTENSIVE research. From the minute I hit send on Paypal, I could not have been happier with my purchase. I had Shipping info in less than 2 hours. The Package shipped next day and was to me here in Texas in just 2 more days. I opened the box, and inspected the product, All pieces accounted for, and in impeccable shape. No rust or damage at all (Comes bare). The fit and finish leave nothing to be desired. It is a top notch product, from a top notch vendor. The Customer service so far has been the best I have ever worked with. Joe is quick to respond, and extremely polite and helpful. I am building Wildland Interface Fire Trucks (Duece&1/2&aposs, 5tons, etc.) ROPS & Brush protection cages. Will be posting some pics up in the next couple of weeks. If you are looking for a easy to buy, easy to assemble, and easy to use bender. Pull the Trigger, this is it.”

Curt

“I’m really enjoying the bender, works great! This was my 1st attempt at doing anything like this and found it very simple to use, a learning curve as with anything new but not bad at all. Highly recommended!!! If I could give any advice to anyone on this it would be to keeps notes on everything you do and save all your patterns. I also bend a perfect 90 and a 180 from every job before starting and hang on to them. Mark and cut them at the block face and I actually mask them off and paint the bend radius. It makes laying out the project so easy. I attached a couple of photos of my project (racing lawnmower), I’ll send more once it’s fully assembled. Thanks Joe!!! Curt”

Daniel

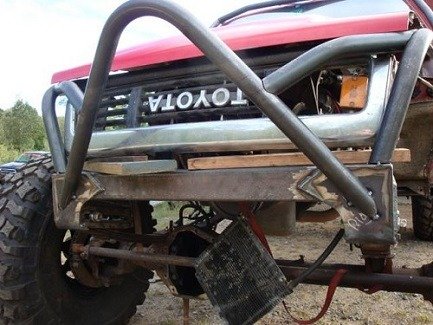

“To start off, my name is Daniel I’m 28, been into offroading for years!! Started building my yota for KOH, raced 2014 KOH ended up blowing 3 tires which took me out of race. I was looking for a bender to start my rear cage and add some more tube on yota, after doing research it came down to JD bender or Rogue. What made me decide to go with Rogue was the price and what you get for the price. Emailed Joe and within a day he emailed me back and hooked it up!!!!!! From time I paid for it and got it in mail was fast!!! Putting bender together was easy!!!!! And right after got it together I started bending, it bends a 180 like nothing, and bends are super clean…. This bender does everything I need and more. Im more then happy to run rogue fab stickers on my yota for up coming races and I’ll send anyone and everyone to Rogue Fab. Customer service and clean parts!!! Dummy proof. Everything fits to a key.. Last thing I wanna add is the size of the bender, so easy to move around and don’t take up any space at all!!!!

Instagram geareddown4x4club. Thanks again Joe for hooking it up!!!!! Seriously go to this guy for everything!!!!

Happy Customer!

“Things are going good, here’s a couple pics so far, bender is GREAT! It has made an -”-awesome compliment to my small personal shop. I am building a crawler/rock bouncer with 18″ of suspension travel. I am finally getting to the part where I am bending more DOM, so will send you more pics as the project progresses. Thanks again, Joe”

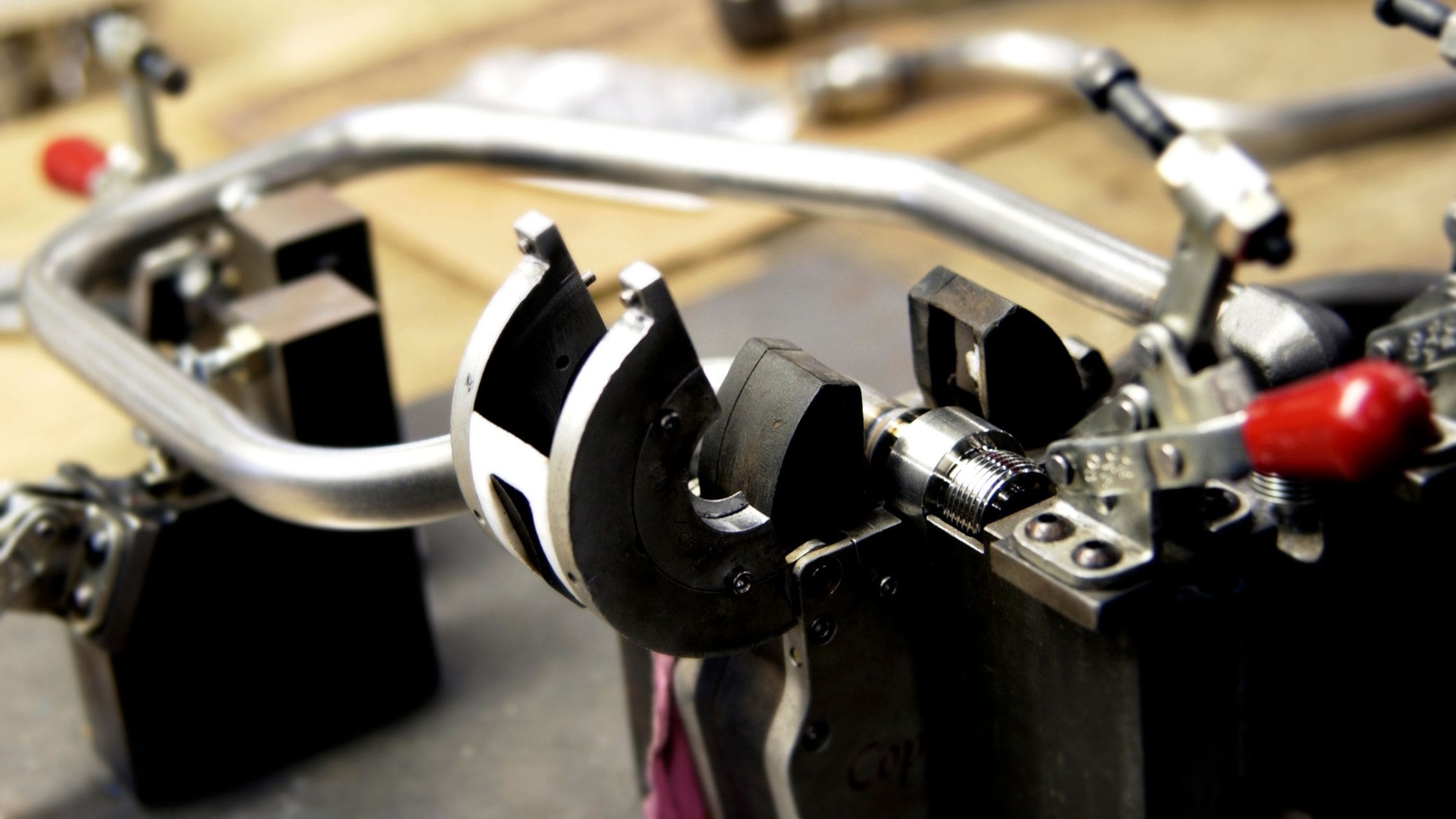

Email we got from Tim the owner at Swamp Water Customs

“A couple weeks back I called you and was picking your brain on how to bend a complete rectangle out of one piece of pipe. Well I was drowning in all the measurements and was very confused. But anyway thanks to you I did it. The pic with the tubing in the bender is with the pressure let off and this is the original length of the pipe. I just had to put a ratchet strap on it to close the 3/4″ gap and weld it up. So needless to say if you do your measurements right you can really do some neat thing with this bender. I am also attaching some pics of the bumper I just built with the Rogue Bender. Thanks for Everything. -Tim, facebook.com/swampwaterkustoms”

Matt – Owner of DFT Plasma Cutting in Santa Maria, CA

Matt is the owner of DFT Plasma Cutting in Santa Maria, CA. he was kind enough to shoot the first video review of our tubing bender. He bought our tubing bender to continue work on his pro-touring car by making a complete 1-off tube frame for it. His car is a 1953 Plymouth Belvedere with C4 corvette front and rear suspension and a Dodge Viper V10 engine. He is a self-proclaimed “tool snob”, and undoubtedly a tough critic, and our tool was up to his standards. Here is what Matt had to say about our bender…

“I recently purchased this tubing bender after months of researching and looking for a used bender. The more I thought about it the more it made sense to buy a new bender and tooling. Some benders are cheap but the tooling is expensive and others are hard to retrofit with a power option. I liked the quality of the parts and pieces, the value of the master kit was an added bonus too. The kit comes well packaged in several layers of cardboard with detailed instructions. Right away I noticed how precise the parts were, the fit and finish of everything is amazing! It took me a few hours to get it together and I must say assembly was super easy. Everything is interlocking so you just square the pieces to the base and tack and move on the next step. The instructions are well written with details you’d expect to find in a quality product. Overall this is a well thought out design and product. The first thing I bent was this piece of Stainless tubing that I had laying around. It’s 1.25″ .120″ it bent it with no problem!”

Clayton of West Texas Gearheadz in Lubbock, TX (806.789.4869)

Clayton built this awesome custom buggy with a Rogue Fabrication Alpha Tubing Bender. It features rockwells and 49″ Iroks mounted to hummer beadlocks and is powered by a 500HP LS6 V8. This rig is running West Texas Gearheads flex joints and spools. The tubework is all 4.5″ CLR bends in 1.75x.120 DOM tubing. Clayton said…

“Bender is kickin ass, thanks for all the tech support! We want to share photos so everyone can see what you are able to create with good tools.”

Chris From Idaho

Chris built this International Scout with a Dana 60 front and a sweet narrowed front end and then later built this awesome rear stinger hinged/removable tire carrier for a TJ.

“I am really impressed with the machine work on all parts. I was expecting a rough plasma cut edge but these were as smooth as a baby’s ass. 10 out of 10! I mock assembled it and again, very precise keying. The parts fit together perfectly 10 out of 10! The instructions are very nice, do you write SOP’s, SWI’s for a living? 10 out of 10!” “To be honest I am amazed at the simple design with light weight materials combined with brute strength I do not see by just looking at it. In my opinion you have re written the book on bender design and price. I cannot say enough good things about it. I hope more people buy and use this bender. I’ll start a fan club for it. Also, you might have unsold yourself on the bigger die (6.0″CLR) as I LOVE how these small radius (4.5″ CLR) bends are easy to tuck into tight spaces. But it is nice to know the option will be available. Thanks for such a great bender!”

James Owner of Custom Industries in Riverside, CA

Custom Industries is a fabrication shop that builds everything from low riders to race car roll cages to lifted show trucks. They even made a porch swing with our bender. It has two pieces of 1.5″ tubing that have a total of 14 bends in them. James said …

“We have made several air bag mounts with your product. We love it!”

Shane in Tilton, NH said

“I wanted to keep the cage as tight as I could so the 4.5 CLR worked out really well. This is all 1.25 A500 Sch 40 (DOM is crazy $ around here) and bends like butter with this bender. I chose the Rogue bender after months of research, I couldn’t find a cheaper way to bend tube up to 180*, you can’t beat the price of the dies if you want to bend multiple sizes and their customer service is top notch. I love how easy it was to put together, that it’s even easier to use, and the fact that you can bend thick walled tube with a simple HD for less than $100. This is my first time ever bending tube and now that I am getting the hang of it, I couldn’t be happier with my purchase.!”

Matt in Carlsbad, CA

NM is creating this one of a kind custom toyota buggy with a Tubing Bender from Rogue Fabrication. The tubework is all 4.5″ CLR bends in 1.75x.120 REW steel tubing.

“I have used it quit a bit making my leaf sprung buggy thing, with good success. The bender is easy to use, portable, duplicates bends accurately and the die block is very handy as a template I use to mark on tube for notching. I especially like the fact that you can take the bent tube out of the bender check it, and put it back in the exact same spot for additional bending, if you leave the clamp die on.”

Jake in Portland, OR

“I am all for new businesses who put out innovative products at affordable prices. Your bender was exactly what we were looking for. No one else on the market can come close as far as price, quality, and customer service.The bender worked great. The first bend took me a couple minutes to figure out but the second was super easy. I’ve never used a tube bender before so this is really a testament to how easy this tube bender is to use. It’s awesome that it is air over hydro and I can just sit back and watch.”

Eric in Portland, OR

“We like it, it bends sweet. Fire the air up couple drinks of your beer and you’re good. Thanks, it’s a sweet set up.”

Josh in Carmichael, CA

“So after hours of research and debates on different benders out there, I bought Rogue’s bender. The way I came to this decision was 2 things; Customer service & I’m lazy. I had called all 3 main bender manufacturers and received the best customer service from Rogue. Not saying the other 2 weren’t good, but my questions and concerns were addressed better with Joe. Anytime I am spending good money on something, I want a peace of mind that there will be someone to help or answer any questions I may have. So I took the plunge and spent the money. I ordered the bender with the 1 3/4” 6″CLR die. After a slight order mix up, and a quick phone call to Joe, I received my bender. A quick note, Joe offered me a T-shirt for the mix up for free. When I opened up the package, everything was there, except the shirt. I thought, “No biggie, it happens”. The next day I received a phone call from Joe @ Rogue Fab. He asked if I had received everything ok, and I replied “YES”. I wasn’t too concerned about the shirt. He then asked if the shirt he promised me was in the box, and I said “No, it wasn’t in there”. He quickly told me that he would have it in the mail, “priority”, to me, and it showed up on my doorstep. The reason I bring all this up is, this is “GOOD CUSTOMER SERVICE”! I’ve since called Joe twice with questions and got legit answers both times.Thanks Joe for everything you’ve done thus far. Here is 2 projects we’ve done and are working on so far.”

Joe

“I’m thoroughly enjoying using my bender. I wouldn’t have been able to get the jobs I’m doing had I not purchased this bender. I’m very happy with it. I couldn’t justify the expense of the units running thousands of dollars. I Thought I’d share a few pics of the projects I’ve been able to complete since getting your bender. It’s done (and is doing) everything I had hoped for. Customers are very happy with the results, as am I. These are all constructed with sch 40 1 ¼” pipe. -Joe”

Tom in Rio Linda, CA

“These racks were fab’d for the top of our forklifts. They are to protect the lift and lights when the product falls off of the boom (happens a lot around here). It’s bent out of .120 wall 1 3/4 electro-welded tubing. The bender had no problem bending this stuff. I’ve done about 20+ bends with it, I haven’t noticed any issues with the bender. This bender is great for out amazingly small maintenance shop. The vertical bending is great for the small area and the fact that we don’t have to bolt it down is nice, we are able to use it then store it in our tool closet. We’ve had it for a few months and used it on a lot of projects. No issues so far, I’m sure if there were any they would handle them down at Rogue Fab” “Rogue Fabrication has some of the best customer service around. If you ever need to get in touch with them they are there or get back to you immediately. I received the bender quickly and it was not hard to assemble due to the precise cuts and slots. I had some questions during the assembly and they were answered with no problems.”

Scott, owner of TS Offroad in Jefferson City, MO

“The bender performed flawlessly. The bend was clean and the bender was quite a treat to use. The air/hydraulic setup was almost fun to use compared to rowing a manual bender. Put in the pipe after calculating my rough bend measurements and hit the air. At 94 degrees I reset the ram and continued bending to 125 degrees. I can’t say enough how easy this is to use… Thanks again for the great product!”

Dan, owner of SWDR4x4 in Las Cruces, NM

“This bender is so simple, just a bit of basic trig, and every bend lines up perfectly!”

Brandon in Aurora, CO

“I bought a Rogue Alpha tube bender having zero work experience on tube, and very limited metal fabrication experience. The bender itself is well built and the instructions are simple and to the point, making assembly very easy. Before bending anything I was very nervous that I had wasted my money and that I would not be able to figure out how to bend correctly… but after the first bend on the Rogue Fab bender, it was clear that this tool is well designed and as a huge bonus for me- it is idiot proof. I have been making great bends since day one. The customer service from rogue fab I have received has been top notch too. A+ in all regards.”

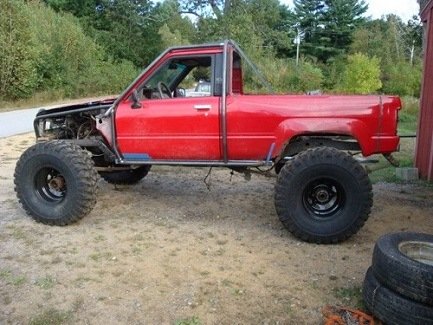

Ian from Champagne, IL

“I Built this rig. 85 Toyota cab and frame. Full tube back half. Rear 4 link. Coil overs with one ton axles. All tube is 1 3/4 DOM .120 wall bent on a RogueFab bender. Love it and tell anyone who’s interested in a bender about it. Great products and excellent customer service. Keep the great products coming.”

Rogue Fab Sponsored Race Cars

Both of these cars belong to Eric Lindquist’s team in Portland, Oregon. They race in the modified class all over Oregon. they are sponsored by Rogue Fabrication, look for our sticker on their car at the track!

John with DNA Fabrication, LLC, in Broken Arrow, OK

“The directions are easy to understand, and assembly is easy. I would recommend a 3/4″ tapered reamer to clean the holes where you weld the washers. Other than that assembly is simple. Once assembled it is very simple to use. I have used it to make a few sets of sliders. After using this bender I can’t imagine going back to my old manual Hossfeld. I would definitely recommend the Rogue Fab bender to for anyone looking for an economical bender.”

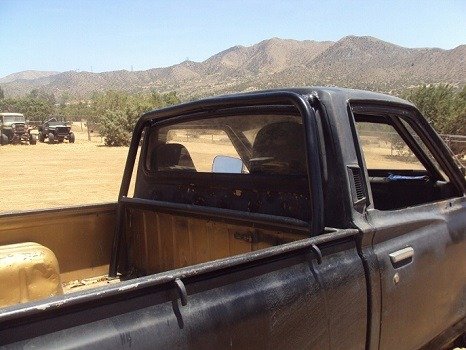

Tommy of Tigard, OR

This beefy winch bumper for a toyota pickup was built by Tommy in Tigard OR. The tube is 1.75 x .120 DOM. His SAS’d pickup is powered by a 7MGE Toyota Supra motor. Tommy said…

“Thanks for the Bender! Works great and is a much better alternative to manually bending 1 3/4 .120 DOM!”

Mike in Tacoma, WA

“I’ve only had the opportunity to bend a hoop for my bumper from some 1.75″ ERW and a play with a few pieces of scrap. I’ll be working with it lots more once I figure out what I want my tube fenders to look like. I also plan to do a proper front cage and a tub-mounted tire carrier, as well as a cross-member, spare-carrier, and bumpers for my pickup. As usual, I have more ideas than time. Thanks for a great tool. I hope that I have more time to use it soon!”

Hoby in Acton, CA

This cool cage was made out of 1.75x.120 DOM tube by Hoby in Acton, CA for his 1974 Datsun. Hoby said…

“I recently purchased this bender. I have used it on 2 projects so far and I liked the way it worked and had no problems with 1.75” .120 tubing, and the guys from rouge fabrications were cool to deal with.”

Autin (Haul N ‘Azz Trikes) in Washington

Autin (Haul N ‘Azz Trikes) uses our bender to make downhill drift trikes in Washington

“The bender works awesome!”

Jason of Distinct Fabrication in Athens, GA

“Got my bender today!! From time of unboxing till first bend was 1.5 hours. Not too bad and the instructions were great. I tested it on 1.5x.120 hrew, 96 degrees in one bend w/o repinning.”

Jordan in Vancouver, WA

This Toyota Pickup belongs to Jordan in Vancouver, WA – Disabled military veteran. Door material is 1.50x.120 HREW bent on a Rogue Alpha Tubing Bender. Jordan said…

“This bender kicks ass! I love it!”

Dylan of 4Wheel Fabrication in Portland OR

This bumper was built using a Rogue M600 Tubing Bender by Dylan of 4Wheel Fabrication. It was made for a Dodge Durango in Portland Oregon. The tube is 1.75 x .120 DOM.

Customer Review

“This looks like a superior design compared to the bending arm design. I really like this. Can’t wait to see what it does with the thick stuff. Keep up the good work.”

From John in Virginia

“I build a 1/2 dozen cages + a ton of bumpers/ sliders and 1-2 buggys a year so making more accurate cuts faster is extra time to spend with my wife and kid. I have had this thing in the shop for over a month now and have been using it a good bit before I am writing this.

While it comes with a tab on the bottom for vise mounting, the location of my vise and wanting to make it more mobile I made a stand for it. It will notch into a bend but takes a min to get it set to do so. Overall it is a well designed unit that has increased the speed and repeatability in the shop.

With everything locked down it provides a stable and accurate cut. The degree indicator built in is spot on and easy to change angles with no tools. The clamp provides a good firm grip on the material without galling it but 5″ is about as short a piece as you can put in it. The new chassis I am building has a TON of notches in it and holesaw life seems to be better than my old notching method so I will also save money there, the hole saw in my video has close to 50 cuts on it and is still in good shape.

I am not trying to sell these things just give a honest review, I do think it’s cool that my review helped them to improve the product. I give it a 5 out 5 and would say it’s a great tool.”

NOTE: John had originally recommended that we include our arbor and also improve the locking collars, we now do both with no change in price -RogueFab

From Randy in Beaverton OR

“I’ve been dreaming of a notcher since I began fabricating 5 years ago. I’m currently working on prototype quadricycles and reverse leaning tricycles which require chromoly and thin walled mild steel. I was doing the old trace and grind sometimes taking a whole day to do a few acceptable notches. After fabing some sleeves (a must for thin wall) the test notches I did on 4130 1.25″x .049 were the best notches I’ve ever done! This unit is beefy. The cam levers make angle selection a breeze. You can crank down the vise, holding the piece solid. The shaft and needle bearings smooth, zero vibration…This notcher is a 10+ and worth every penny. You won’t be disappointed. Cant wait to bust out the tig rig and get to sewing together some chromoly!

Joe at RougeFab has awesome customer service. If he couldn’t answer the phone he responded uber speedy to messages and texts. Plus I’m lucky because RougeFab is in the neighborhood so I was able to will call and pick it up in 10 minutes. Next on the list is the bender and selection of dies!”

From Ward in Orlando FL

“I wanted to take a minute and tell you what great products you have. I bought a 1 1/2″ .120 wall DOM tubing bender with the HD kit and your VersaNotcher. They are fantastic and both very impressive.

My son works in Denver where he has got into rock crawling and loves it. He drove his 2014 Jeep JK to Orlando to be with us for Christmas. I said as long as he was here for a few days we would put new gears in it and bend up a tire carrier. We are both hobbyists when it comes to mechanics and metal fabrication but we can get it done. Attached are few pictures of his Jeep just before he headed back to Denver. It took us a couple tries to get the hang of the bender but when it clicked it was very easy to use. I took a picture of a few feet of waste but when you consider the complexity of the bends on the swing out tire carrier it was nothing. He bought the fender armor and we fabricated and welded the carrier mounts to them. We also made a new bumper with a built in receiver for recovery. The carrier will hold and swing a 37″ mounted tire. Unfortunately we did not have time to bend up the fenders and rock sliders but there is always next time.

The gears kicked our butts but turned out great. On the bright side all the fab work and welding only took couple days and was a ton of fun. I think there is going to be a 383 stroker tube buggy in my future. We are hooked!!!!”

From Customer

“I run a mobile fabrication business, and I have been looking for a good notcher that is very versatile. I have tried a Woodward notcher (not good), a jmr race line (good but not versatile), the TN-250 (great but too heavy for easy moving on the fab trailers). The best one yet is the versa notcher. Its very rigid, “light” weight (17lbs to ups) but the most important its very accurate I notched a test piece in a 1x2x120 tube 1/2″ off set at 60 degrees for 15/8 tube it was within 3/100 of a degree on a 60 with less than than .005 gap against the tube. This is by far the best notcher I have ever used and 400 shipped to the door is a steal! I would have paid 1000 for one this good if you want a great notcher with stellar service get the versa notcher. I’m in no way affiliated with Rogue Fab just thought every one should know they sell a great notcher. I will keep you updated on the wear and tear on it only time will tell if remains the best.”