Titanium is a versatile material, and titanium tubes form the basis of structures like aircraft frames, racing car roll cages, and oil rigs. They are put to work in some of the most severe environments. Titanium’s high strength is the main advantage that makes these tubes perfect for such applications.

In cases like roll cages, well-designed and carefully welded titanium tubing safeguards the human life inside, increasing driver safety. Titanium tube bending is an essential part of fabricating such products.

This article explores how a titanium tube bending machine is used, its benefits, and how to choose one.

How hard is it to bend titanium tubing?

The difficulty of bending a pure titanium tube or alloyed grades of titanium depends on the method you employ for the bending process.

One of the challenges associated with bending titanium is its high modulus of elasticity. Its low uniform elongation makes it difficult to machine and form. Much greater bend radii are required when compared to other metals. It is also susceptible to hydrogen embrittlement and fatigue cracking.

Without a specialized titanium tube bending machine, it’s almost impossible. Even with manual tube benders, the process can take a lot of effort to bend/form even a thin titanium tube. Even hot bending requires a certain degree of effort and lots of time.

However, with high-end tube benders like RogueFab’s benders designed for the purpose, it’s a piece of cake to bend titanium. RogueFab’s benders make things even easier with hydraulic add-ons that can bend at the push of a button.

What to Look For When Buying a Titanium Tube Bender?

Making a careful choice when buying a titanium tube-forming machine can be the difference between a high-strength construction and something that leads to a fatal accident. Here are the things you should consider to get a precise bending machine:

Maximum Bend Angle

The maximum bending angle is one of the most important factors when choosing a tube bending machine. This angle refers to the bending capacity of the machine or how far it can bend. A greater maximum bend angle allows more options for possible uses.

Single Turn Bending Angle

The single-turn bending angle is how many degrees a machine can bend a tube in one uninterrupted manufacturing cycle. The greater this angle, the less effort and time are required to produce the specified bend in the titanium tubing. This leads to a faster overall production time.

Build Quality

It is better to invest in a high-quality tube bending machine with corrosion resistance properties so that it will last longer. For instance, RogueFab’s tube benders are known for their anti-corrosion, durability, and build-quality features.

Hydraulic vs. Mechanical Tube Bender

Bending titanium tubing is not as easy as forming softer tubes such as copper. A hydraulic bending process provides an easier way to bend these tubes as the physical force is provided by the hydraulic systems instead of manual action.

Bending Diameters

Every tube bender has its range of diameters it can bend. A wider bending diameter range gives greater versatility. An important thing to note is that only the correct tooling should be used for bending tubes with different diameters to meet the dimensional tolerances provided in the specifications.

Benefits of RogueFab Titanium Tube and Pipe Benders

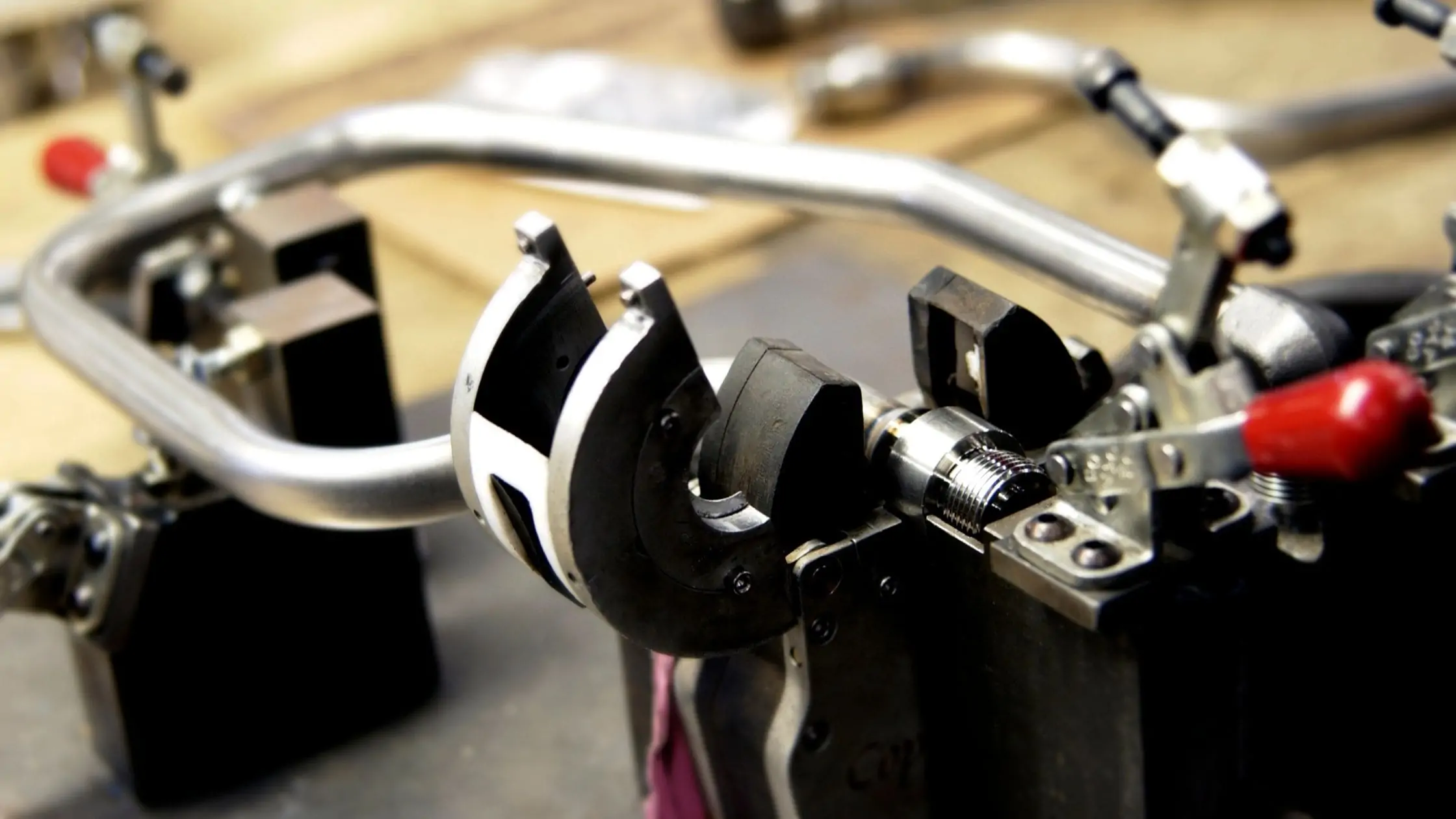

Many reasons make RogueFab’s benders the best for bending a wide range of versatile materials. Some, such as the M600 mandrel benders, are the industry-leading products preferred by professionals in every manufacturing sector. These benders can bend any metal tube, from aluminum, titanium, and super duplex stainless steels to exotic alloys – all to the same tolerances.

These benders are widely used for manufacturing high-performance exhaust systems. The diameters of the tubing for these applications can be up to 2 inches. For some applications, the diameter can be pushed to 2 1/4 inches. These benders can manufacture turbo manifolds and motorsport components in-house instead of outsourcing them, saving costs significantly.

Additional features include adding hydraulic systems that can bend titanium at 3.5 degrees per second. This bending speed is three times faster than conventional mechanical bending, improving production parameters. One of the best things about these benders is that they can create bends bidirectionally. This is better than many other popular tube-bending machines that only bend unidirectionally.

Lastly, these machines and any compatible tooling you get along with them come with some of the most extensive warranties that any manufacturer offers. This reflects the confidence Rogue Fabrication has in the build quality of its products.

Conclusion

Bending titanium can be difficult, so you need a professional tube bender, such as those from RogueFab. Inferior tube benders end up causing damage to the tubes or even the operator, leading to more losses than what you save initially. Therefore, it is always a good idea to invest one time in a superior titanium tubing bender such as the M600 and enjoy long-term savings in terms of faster production, higher quality bends, and longer machine life.