Author: Joe Gambino

How to Start a Fabrication or Manufacturing Business

by Joe Gambino | Mar 19, 2025 | TechGet paid to do what you love! Be your own boss! Starting a new business is exciting but can also be challenging and risky. With our help, you can minimize the risk and easily get…

Copper Tube Bender

by Joe Gambino | Sep 8, 2022 | TechRogue Fabrication specializes in designing and manufacturing high-quality metalworking tools. We know the secret of pipe benders that produce consistently perfect results. Rogue Fabrication products are made in the USA, but worldwide shipping is available….

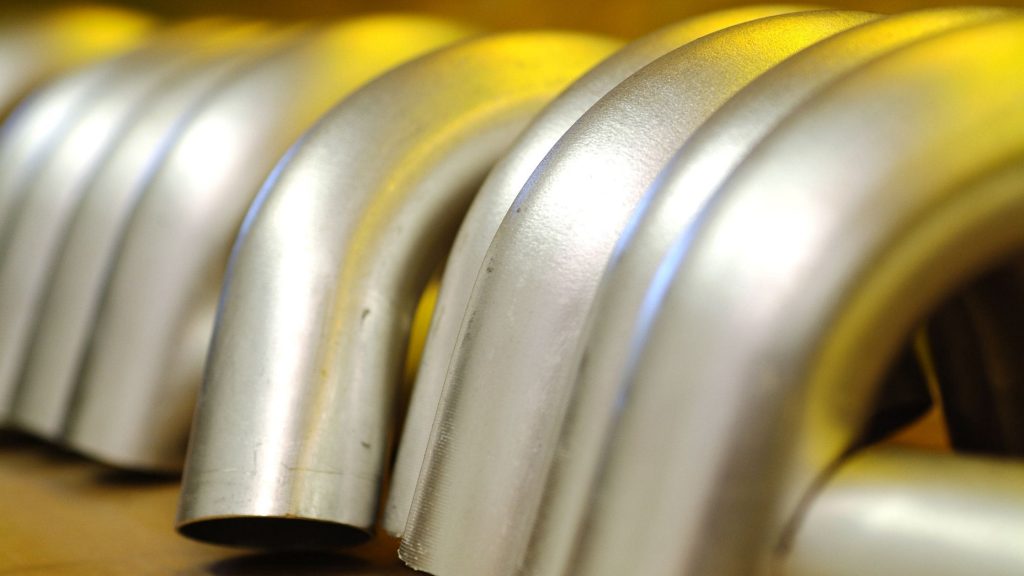

Stainless Steel Tube Bender

by Joe Gambino | Sep 6, 2022 | TechStainless steel is one of the most common materials for making pipes and tubes for wide-ranging applications. These tubes undergo several processes to make them usable, one of which is tube bending. Tube bending sounds…

Brass Tube Bender – A Quality Tool for Perfect Bends Every Time

by Joe Gambino | | TechRogue Fab has done it again with their new and improved Metal Tube Bender M601! This standard/heavy-duty brass tube bender is ideal for bending most configurations of tubing, such as aluminum, copper, and more. The…

What are the Different Types of Tube Bending and the Types of Pipe Bending Machines

by Joe Gambino | Sep 5, 2022 | TechPipe bending is one of the most commonly used processes in most fabricator workshops. From making roll cages to frames of furniture, bending the pipe is essential for every application when it comes to metal…

Titanium Tube Bender

by Joe Gambino | Aug 31, 2022 | TechTitanium is a versatile material, and titanium tubes form the basis of structures like aircraft frames, racing car roll cages, and oil rigs. They are put to work in some of the most severe environments….

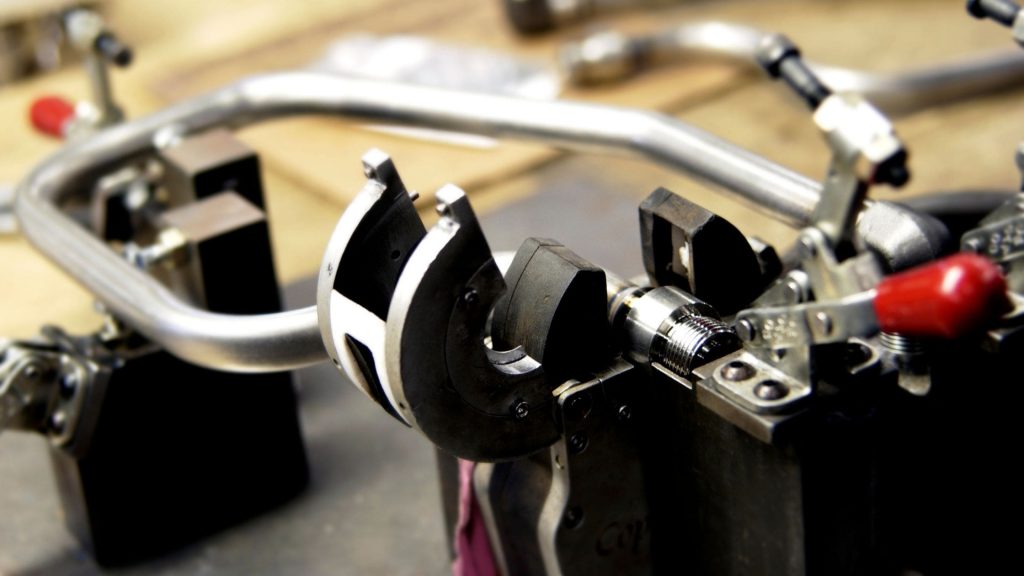

What is Mandrel Bending – Different Applications, Types and Processes

by Joe Gambino | Aug 1, 2022 | TechProfessionals often recommend mandrel bending as the safest method of making a bend in a tube/pipe without harming it. But what is mandrel bending, and how do you make mandrel bends in pipe bending. This guide…

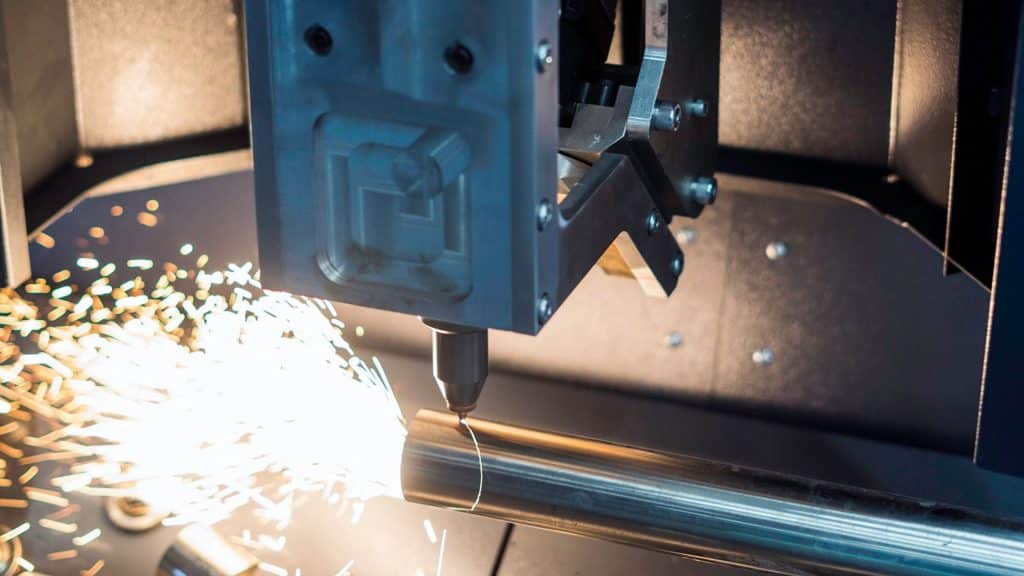

What is Tube Notching – Applications, Types and Process

by Joe Gambino | | TechTube notching is used extensively in any workshop that handles tubing or pipes. While tube notching goes hand in hand with tube bending, the process is not simple. Many people aren’t aware of how it…

July/August 2022 Drawing Prize!

by Joe Gambino | Jul 7, 2022 | DrawingsLive Video Link: LIVE YouTube VIDEO LINK HERE Grand Prize (see below): $3279.50 package! See Below Runner Up Prize #1: $50 Gift Card Runner Up Prize #2: $25 Gift Card Donation Recipient (for donated…

May/June 2022 RogueFab Sweepstakes Drawing!

by Joe Gambino | May 6, 2022 | DrawingsLive Video Link: LIVE YouTube VIDEO LINK HERE Grand Prize (see below): $3123.00 package! See Below – Winner Adam Northup Runner Up Prize #1: $50 Gift Card – Keith Minnicks (doubled, he was watching live!)…

Mar/April 2022 Drawing – Google Review Entry Option!

by Joe Gambino | Mar 8, 2022 | DrawingsLive Video Link: LIVE YouTube VIDEO LINK HERE Grand Prize (see below): $4338 Roll Cage DREAM Package! (1.5/1.75 configuration) – Steve Bresmahan Runner Up Prize #1: $50 Gift Card – David Campbell Runner Up Prize…