Description

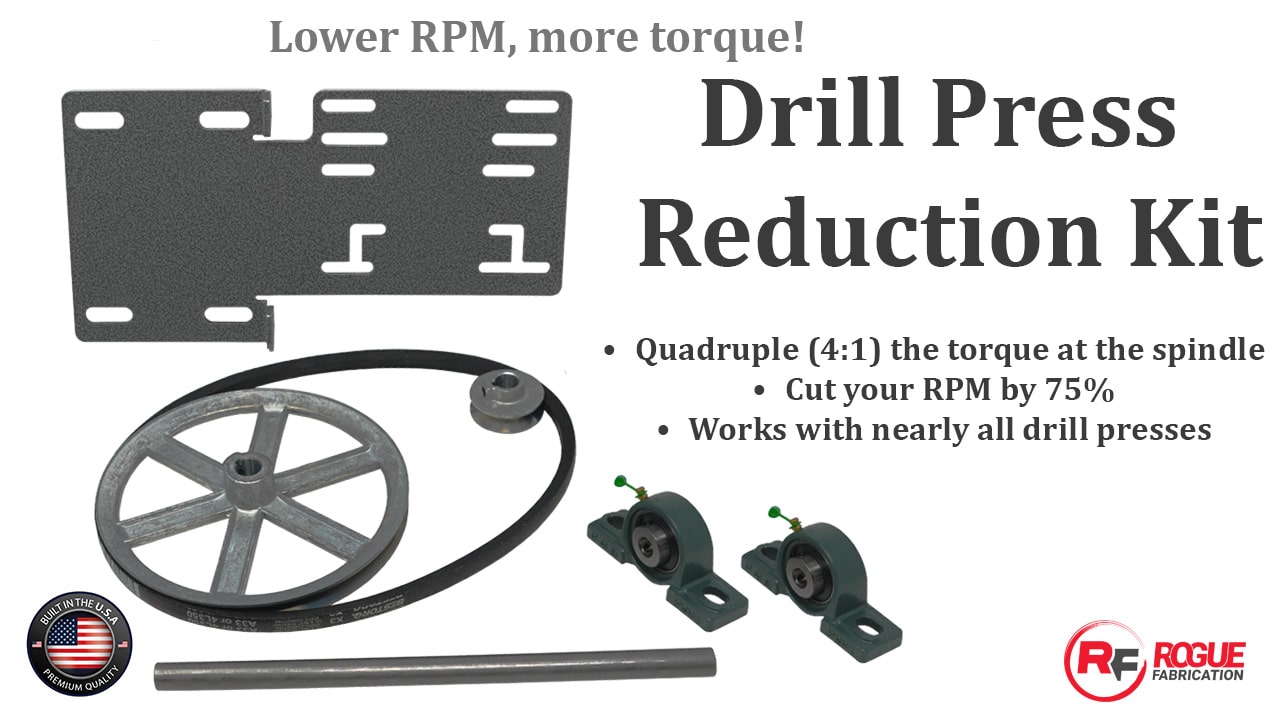

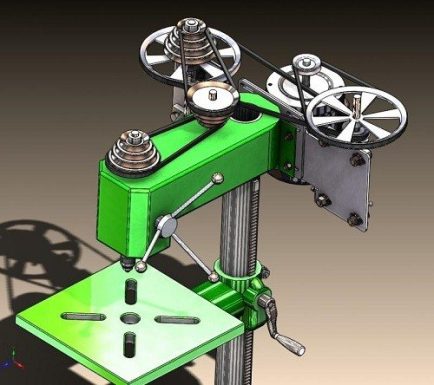

Want to slow down your drill press? This bolt on kit will quadruple (4:1) the torque of your drill press at the spindle and cut the RPM by 75%! Kit bolts on in about 25 minutes with hand tools. Requires trimming of your belt guard if equipped. You may have to purchase a separate belt if the one we provide does not fit. Works with nearly all drill presses. Click on the Tech link below to find out if your drill press works with this kit. This kit uses cold rolled steel shafting, high quality cast-iron block mounted greasable ball bearings, and ships raw (the main plate is not painted). If want your drill press to go slower and have more torque, this is the kit you should order.The 4:1 is our most popular kit, and the one we almost always recommend. Also, it is very important that the shaft size of the kit you order matches your drill press motor. The belt size of the kit doesn’t need to match your drill press at all.

Click here (new tab) for Drill Press Reduction Kit tech (way more info)!

18 reviews for Drill Press Reduction (4:1) Kit, lower RPM, more torque!