Description

***Appearance notes: We are in the process of changing from a bolt-on steel lower shelf to an easier-to-assemble lower shelf that looks nearly the same, but has the frame structure incorporated into the shelf. Once this change is made, the whole cart will be hammered grey (shelves won’t be black anymore).

These are awesome carts for our tubing benders. The Tradesman model comes ready to be welded or welded and powder coated (as of 2/24/2022, we may be painting these in hammered grey instead of powder coating them due to national powder coat supply issues), and loaded with excellent features like:

Ultra Heavy duty ball bearing casters with locking 5″ wheels, and pivot locks. These are nicer than the casters on $3K tool boxes.

Heavy steel construction (these weigh about 85#!)

Massive 1200#+ load capacity

Hooks for wrenches (3)

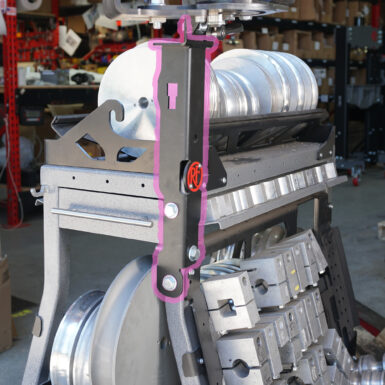

locks and clamps to secure our tubing bender

Lower shelf if CNC laser cut from structural steel and formed on a CNC press brake

Every part is made in the USA except the nuts/bolts/wheels.

Add the VersaNotcher Pedestal Mount to mount your notcher to your cart as well! NOTE- Many of the images show our ELITE cart (not the Tradesman). Look at the first image to see what the tradesman cart looks like. Our dimensional photos, rack compatibility photos, and bender scale/fitment photos are great ways to see what all of our carts can do, but they may show additional options and may show the ELITE cart, not the Tradesman.

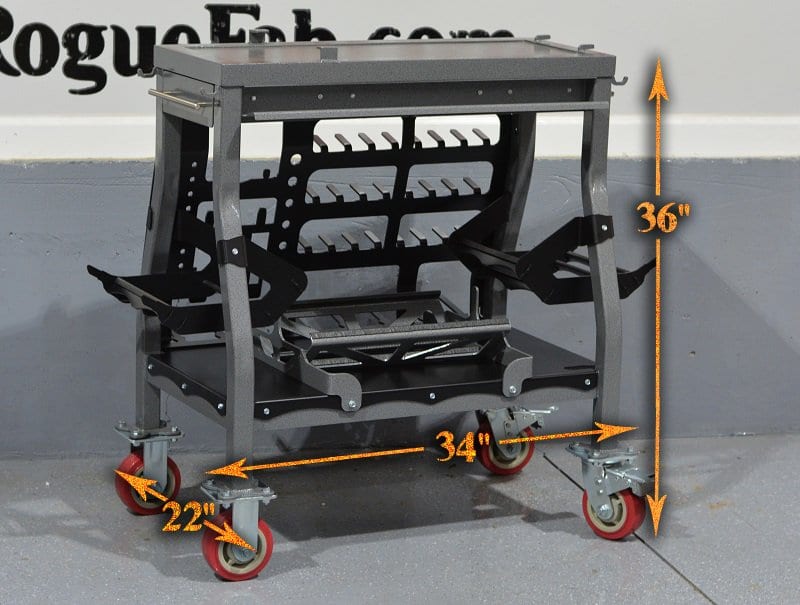

Machine Dimensions:

M6xx tubing bender: (assembled, ready to bend): 12”x30” floor footprint. Overall dimensions 12”x47”x32” (LxWxH). Weight 140-200 lbs.

M6xx Bender on Cart: 22”x34” floor footprint. Overall dimensions 22”x47”x68” (LxWxH). Weight 210+ lbs (depends on cart contents).

8 reviews for TRADESMAN M600 Bender Cart