Description

Patented under USPTO 11,478,838

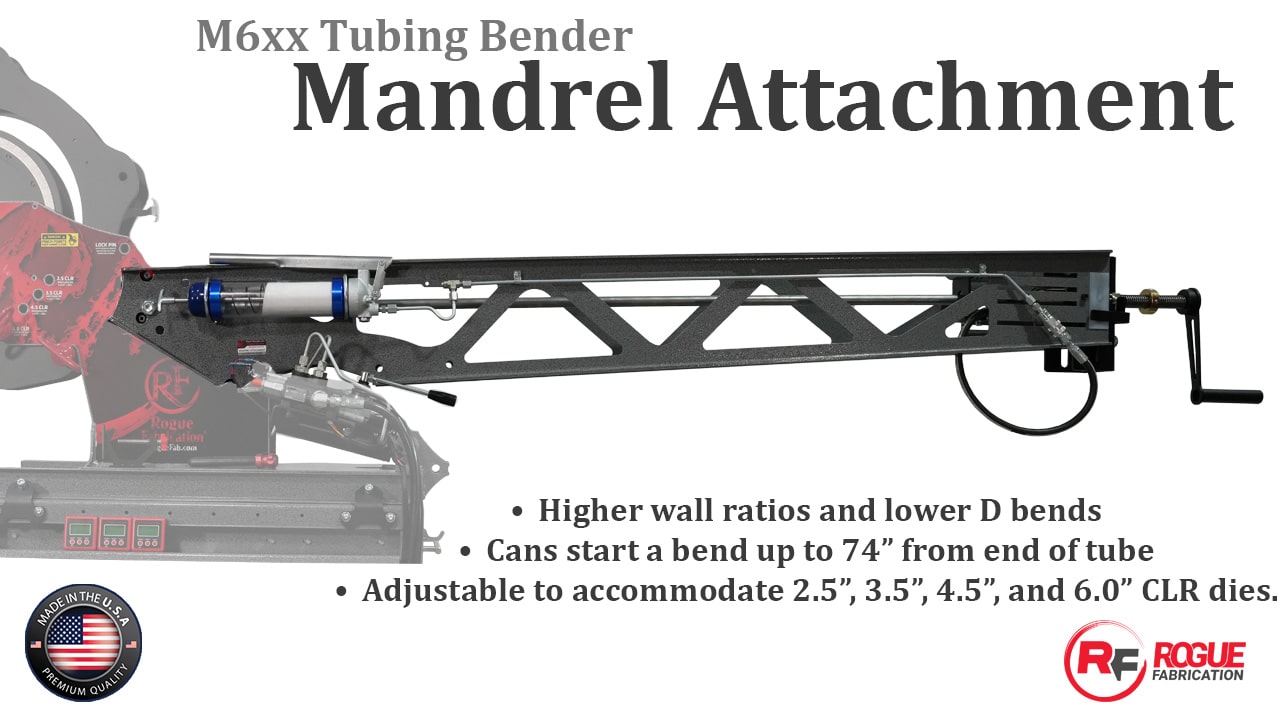

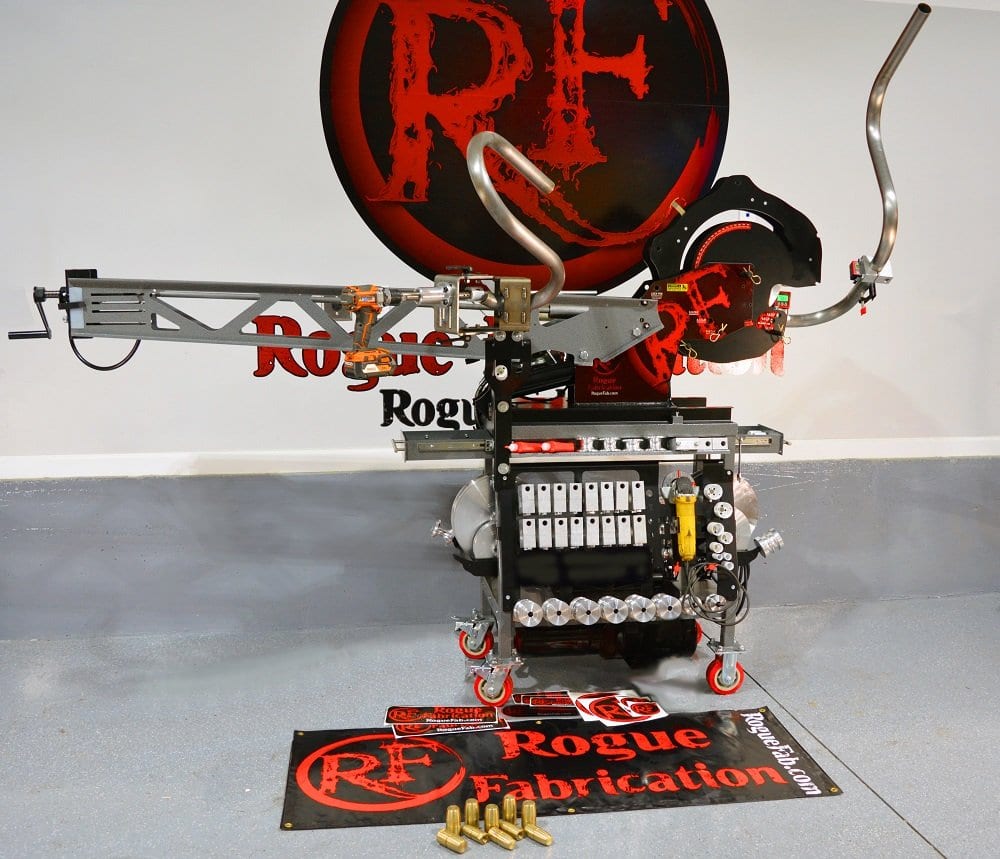

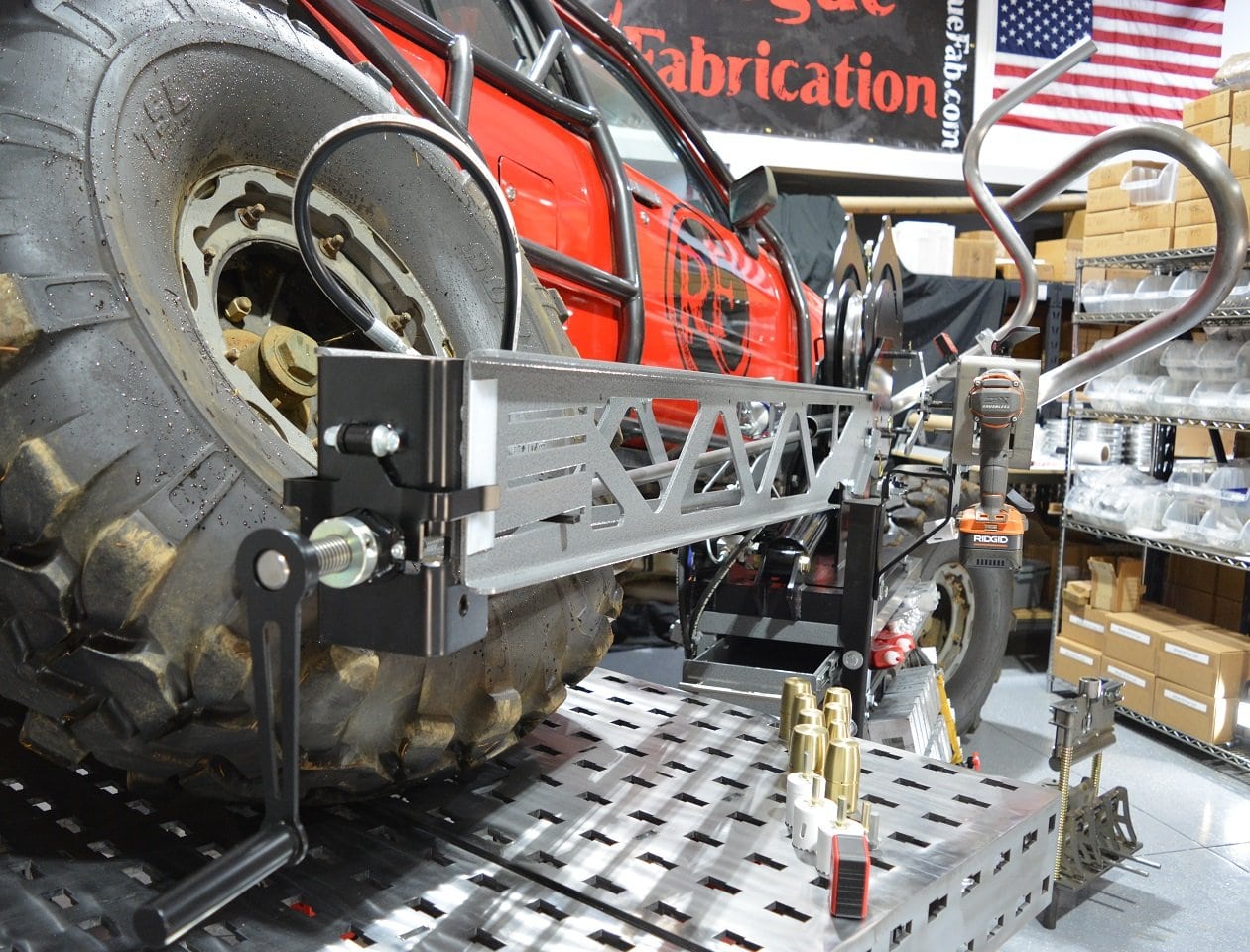

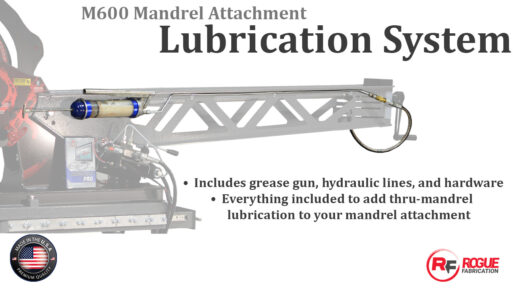

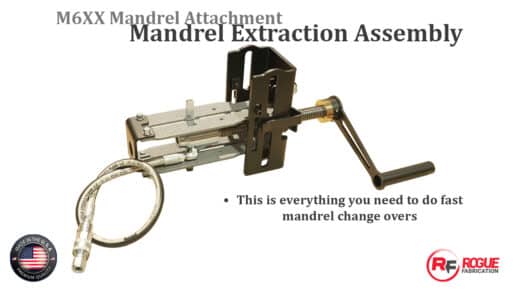

This attachment transforms any M6xx series bender (M600, 601, 605, or 625) into a true mandrel bender. It features CNC laser-cut and formed A36 steel frame components for exceptional accuracy and rigidity. The massive 1″ ACME drive screw allows for effortless mandrel extraction. If you choose to upgrade your setup with our thru-mandrel lubrication injection system, you’ll benefit from extended mandrel life and even better bending performance.

On this page, we walk you through everything you need to know about how our mandrel bender works, including how to order one and make sure you have everything required.

This system is vertically adjustable to accommodate 2.5″, 3.5″, 4.5″, and 6.0″ CLR dies. The mandrel position is also front-to-back adjustable, allowing for precise tuning just like on industrial $100K+ mandrel benders. A locking ACME nut lets you save the mandrel position for easy repeat bends. This attachment is designed to be used with our high-nickel bronze alloy mandrels, which offer exceptional strength and natural lubricity, again, just like those found on six-figure machines.

With this upgrade, you can easily bend thin-walled titanium, stainless exhaust tubing, header elbows, turbo manifold tubes, and more. We keep detailed records of all our testing, including mandrel positions, so you can tap into our experience and apply it directly to your shop’s success and profitability.

This attachment makes the RogueFab Model 600 the most affordable mandrel bender in the world capable of bending over 1″ OD steel tubing. And it’s all made in the USA, from the mandrels and frame components to the machined parts and ACME screw. Only minor hardware is imported. Maximum bending diameter remains 2″, just like the standard M6xx bender without this attachment.

The system can start a bend up to 74″ from the end of the tube, with infinite range on the front-facing side of the machine. For those needing to bend 20+ foot lengths of tubing mid-span, we offer length extensions (link).

What’s new in Version 2.0?

The updated frame design includes expanded capabilities for handling higher wall ratios (thinner tubing) and lower D bends (tighter radii). It is also compatible with the next-generation tooling we began developing in 2022 for even more advanced bending performance.

Note: No mandrels or lubrication are included with this attachment. Please return to the Mandrel Bender product category to shop for mandrels and lubrication. This attachment can be wall-mounted using our dedicated storage racks (link). When installed on your M6xx series bender, the complete system spans approximately 10 feet in length.

More info on the mandrel tube bender machine in our videos:

Mandrel bender in action:

Ordering Tips:

We’ve been designing our machines to work with the mandrel attachment for years, although this capability wasn’t included at the very beginning of our product development. Please read this entire section carefully to ensure you understand everything required to successfully use the mandrel attachment.

-

You must have a functioning bender to use the mandrel attachment.

-

Just like your M6xx series bender requires a die for each tube size, the mandrel attachment requires a mandrel for each application.

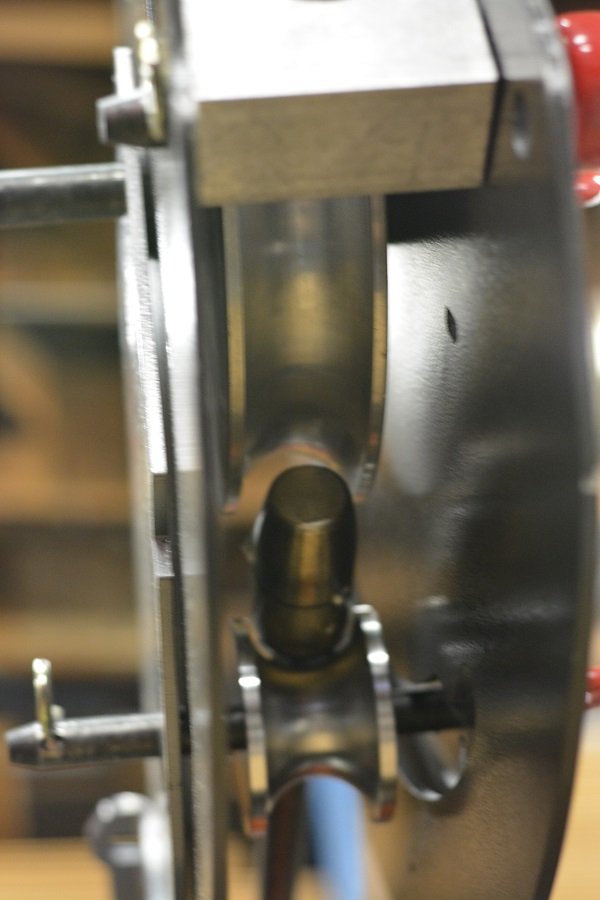

The mandrel is the bullet-shaped component that supports the inside of the tubing during bending. You can see it in action in the videos above. -

Every die you plan to use with a mandrel must have a roller pressure die.

For any application with a Center Line Radius (CLR) larger than 4.5″, you will need two (2) roller pressure dies. This is critical for proper function and bend quality. -

Mandrel bending involves high friction and requires lubrication.

We recommend and sell a high-performance lubricant, Bend All 004, specifically designed for this purpose.

MACHINE COMPATIBILITY:

Fully Compatible (No Modifications Needed):

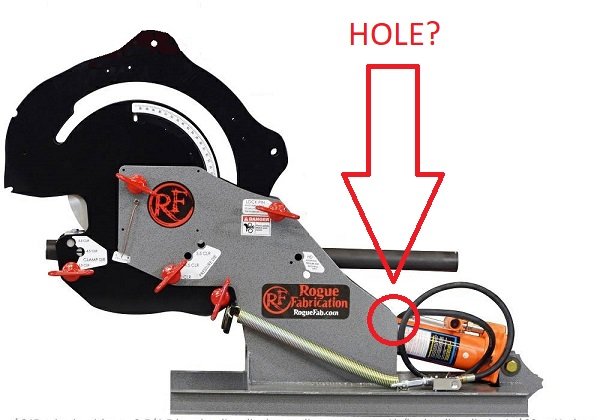

Any machine that has a hole where the arrow in the diagram is pointing is fully compatible with the mandrel attachment. This includes all machines manufactured after mid-2016.

Compatible with Simple Modifications:

Machines that do not have the hole indicated in the diagram, but were made between November 2014 and mid-2016 (standard and xHD models), can be made compatible with minor modifications. We offer retrofit kits that include weld-on tabs and templates for these models.

Not Compatible:

Machines built before November 2014 are not compatible with the mandrel attachment. Please refer to our FAQ section for guidance on determining your machine’s manufacturing date.

Here is a Model 600 from mid-2014. This machine can work with the mandrel attachment, but it requires modifications, and we have not yet developed a retrofit kit for it. Please note that it is only compatible with 3.5″ and 4.5″ CLR dies when used with the mandrel attachment. It cannot be used with 6.0″ CLR dies for mandrel bending.

This setup may be compatible with the TWR (Thin Wall Roller), but it is not compatible with the Backstop assembly, as both attach to the same location. It works with all of our carts and is fully compatible with all RogueFab electric/hydraulic power systems.

The following models are supported: M600 xHD, M600 HD, M605, and M625.

M600 Standard and M601 models can also be used, but must be converted to HD or M605 specification prior to compatibility.

This system also works with our pedestal mount when used on a cart with a VersaNotcher, but only if our offset bracket is installed. Please refer to the VersaNotcher listings in our store for more information about the offset bracket.

Array ( [width] => 3024 [height] => 4032 [file] => 2018/09/IMG_0134-rotated.jpg [filesize] => 1503657 [sizes] => Array ( [woocommerce_thumbnail] => Array ( [file] => IMG_0134-rotated-289x385.jpg [width] => 289 [height] => 385 [mime-type] => image/jpeg [filesize] => 22670 [uncropped] => ) [woocommerce_gallery_thumbnail] => Array ( [file] => IMG_0134-rotated-113x150.jpg [width] => 113 [height] => 150 [mime-type] => image/jpeg [filesize] => 4812 ) [woocommerce_single] => Array ( [file] => IMG_0134-rotated-416x555.jpg [width] => 416 [height] => 555 [mime-type] => image/jpeg [filesize] => 42204 ) [medium] => Array ( [file] => IMG_0134-225x300.jpg [width] => 225 [height] => 300 [mime-type] => image/jpeg ) [thumbnail] => Array ( [file] => IMG_0134-113x150.jpg [width] => 113 [height] => 150 [mime-type] => image/jpeg ) [wcpr-photo-reviews] => Array ( [file] => IMG_0134-375x500.jpg [width] => 375 [height] => 500 [mime-type] => image/jpeg ) ) [image_meta] => Array ( [aperture] => 0 [credit] => [camera] => [caption] => [created_timestamp] => 0 [copyright] => [focal_length] => 0 [iso] => 0 [shutter_speed] => 0 [title] => [orientation] => 0 [keywords] => Array ( ) ) )Array ( [width] => 3024 [height] => 4032 [file] => 2018/09/IMG_0139-rotated.jpg [filesize] => 1232336 [sizes] => Array ( [woocommerce_thumbnail] => Array ( [file] => IMG_0139-rotated-289x385.jpg [width] => 289 [height] => 385 [mime-type] => image/jpeg [filesize] => 11626 [uncropped] => ) [woocommerce_gallery_thumbnail] => Array ( [file] => IMG_0139-rotated-113x150.jpg [width] => 113 [height] => 150 [mime-type] => image/jpeg [filesize] => 3240 ) [woocommerce_single] => Array ( [file] => IMG_0139-rotated-416x555.jpg [width] => 416 [height] => 555 [mime-type] => image/jpeg [filesize] => 20091 ) [medium] => Array ( [file] => IMG_0139-225x300.jpg [width] => 225 [height] => 300 [mime-type] => image/jpeg ) [thumbnail] => Array ( [file] => IMG_0139-113x150.jpg [width] => 113 [height] => 150 [mime-type] => image/jpeg ) [wcpr-photo-reviews] => Array ( [file] => IMG_0139-375x500.jpg [width] => 375 [height] => 500 [mime-type] => image/jpeg ) ) [image_meta] => Array ( [aperture] => 0 [credit] => [camera] => [caption] => [created_timestamp] => 0 [copyright] => [focal_length] => 0 [iso] => 0 [shutter_speed] => 0 [title] => [orientation] => 0 [keywords] => Array ( ) ) )