Description

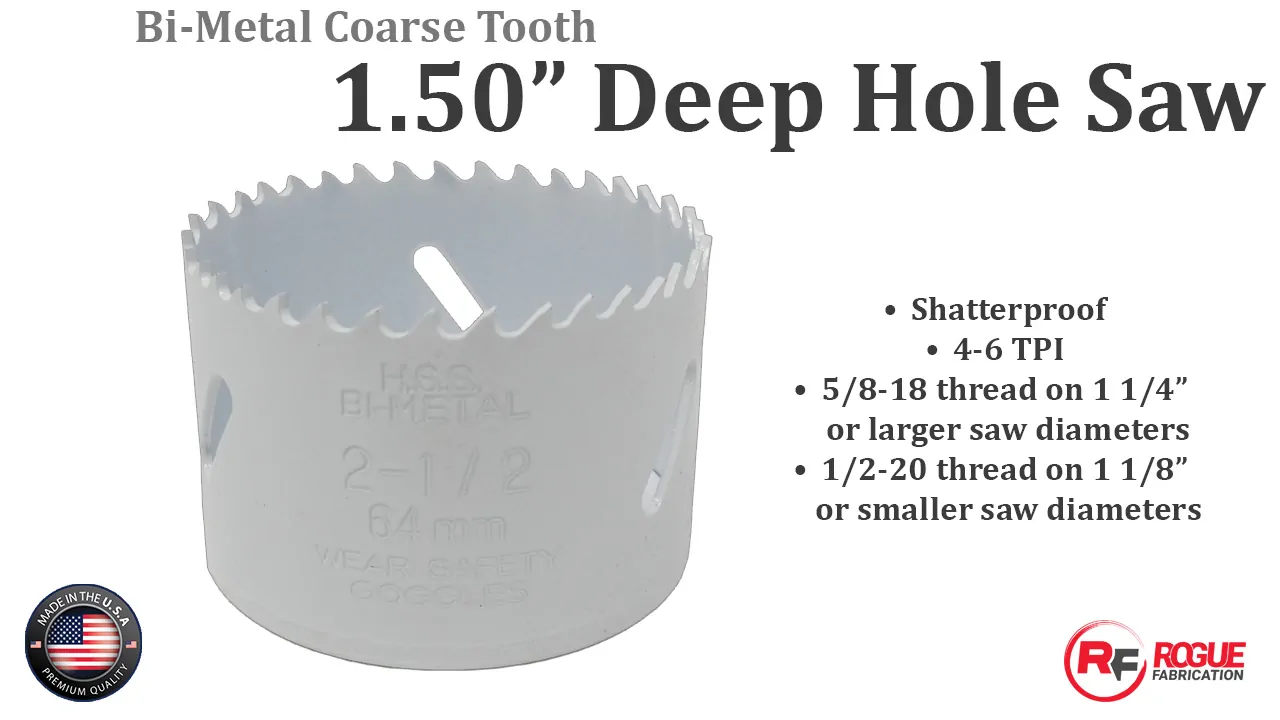

These are excellent hole saws at a great price. Stock up and be prepared for any notching job.

*Made in the USA

*Shatterproof

*4/6 TPI variable pitch

*Standard 1.5″ cutting depth

*5/8-18 threads on 1 1/4″ cutting diameter and larger (uses our standard “Large” arbors)

*1/2-20 threads on 1 1/8″ cutting diameter and smaller (uses our standard “Small” arbors)

How to select a hole saw for your needs:

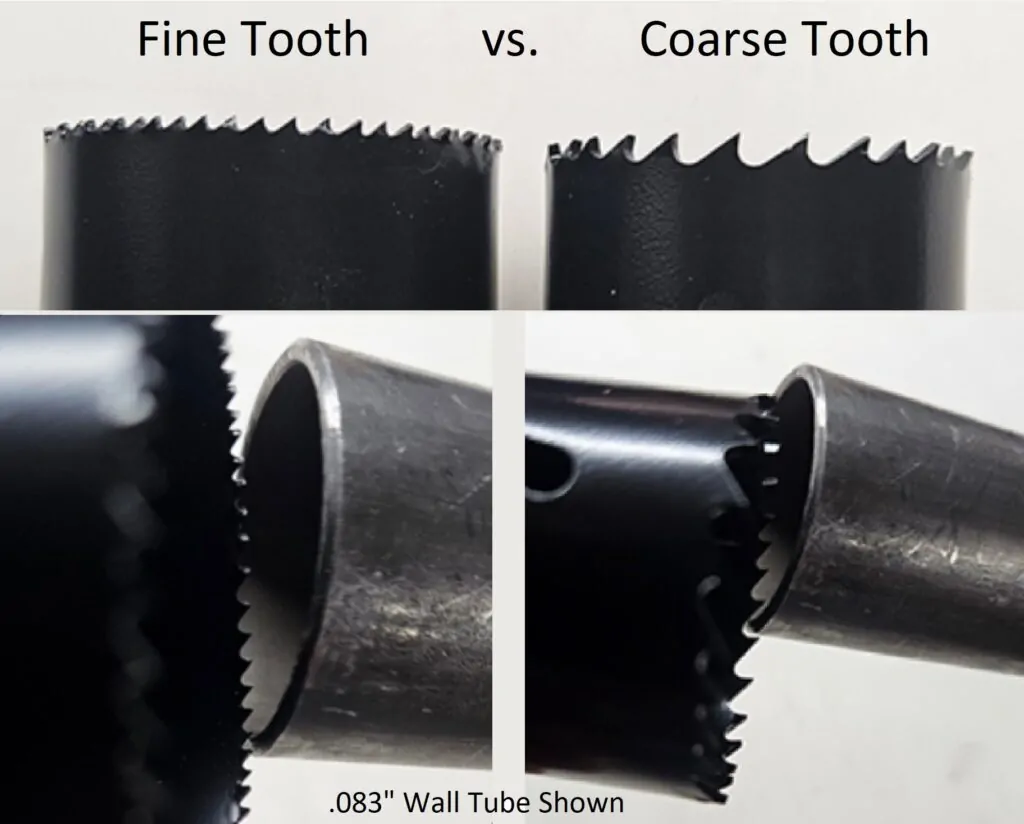

Coarse vs. Fine Tooth:

Coarse tooth: Coarse pitch hole saws are common, like the Starrett/Milwaukee/Irwin/Lennox ones you’re used to. They have a variable tooth pitch that ranges from 4 to 6 teeth per inch (TPI). These cut fast and resist clogging. They are also easier to overload when cutting due to the large teeth, and they are slightly less precise. If you’re notching tubing that is thin enough to fit between the teeth (1/6″ = .167″), you may consider a finer tooth hole saw. We generally recommend a coarse tooth for any metal thicker than .095″. Coarse tooth hole saws are slightly LESS beginner-friendly due to their ease of overloading the teeth during a cut.

Fine tooth: Fine pitch hole saws are only made by Deep Saws as far as we have seen. They have a variable tooth pitch that ranges from 8 to 12 teeth per inch (TPI). These cut slower and are easier to clog, especially on aluminum. They resist overloading, even when cutting thin-walled metals. They are the most precise hole saws on the market. If you’re notching/cutting tubing .095″ thick or below, we recommend fine tooth hole saws.

Depth:

1.5″ (Standard): Standard hole saws have a 1.5″ cutting depth. IF you go buy hole saws from ten different manufacturers online or in stores, this is what you are likely going to end up with (unless they are Deep Saws brand). This is fine for 90-degree notches on 1.5″ diameter or smaller material only. Once you increase the diameter or change the angle, you run out of depth and have to grab a grinder to trim out the chunk of tube that is stopping the hole saw from making forward progress.

2.0″ Depth of cut: Deep Saws make fine tooth hole saws in 2″ cutting depth, and we carry them in fine pitch only. These are the most affordable fine pitch saws on the market. They also have just enough depth to do some angled notches in tube diameters under 2″, and 90-degree notches in 2″ tube. A huge benefit to these hole saws over 3″ and longer ones is that they fit easily in every tube notcher (not just ours), and they are still short enough to be very rigid, which is beginner-friendly.

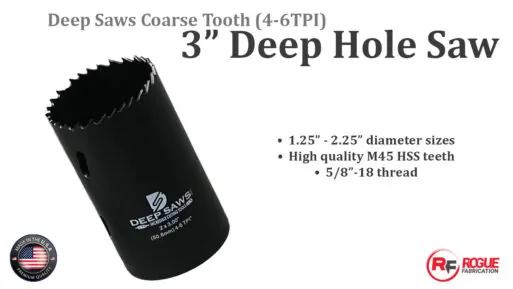

3.0″ Depth of cut: Deep Saws makes the only 3″+ cutting depth hole saws for general metalwork, and we carry them in coarse and fine pitch. The longer your hole saw is (and the smaller your tubing is), the more you can deviate from a 90-degree tube notch without bottoming out the hole saw. A 3″ depth is generally deep enough for most applications up to 1.75″ OD tubing. See below for an exact angle comparison between 3-hole saw depths on the same diameter of tubing. Deep saws have the most rigid design on the market, but all metal behaves as a spring (no matter how stiff it is). For this reason, 3″ hole saws are slightly less beginner-friendly than shorter hole saws. Once you learn the finesse required to keep the drill RPM and feed pressure within limits to keep a healthy cut rate, they last a long time and are easy to run without grabbing mid-cut.

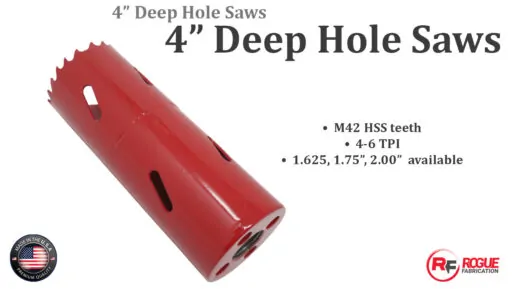

4.0″ Depth of cut: Deep Saws makes the only 4″ cutting depth hole saws for general metalwork, and we carry them in coarse and fine pitch. Please see the discussion above about 3″ deep hole saws. The same information applies to 4″ deep hole saws, but they require just a fraction more finesse and control to master.

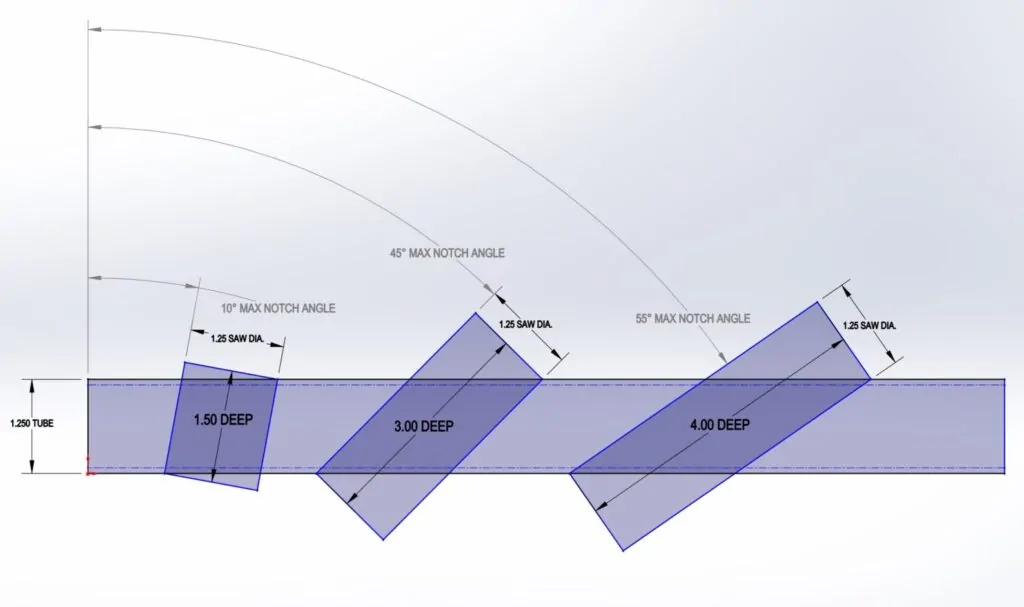

Notch Angles: As you can see, a 1.5″ deep hole saw only allows an angle of 10 degrees on 1-1/4″ diameter tube. Longer hole saws save you time and allow angles of up to 55 degrees in a single cut!

1 review for Hole saw, bi metal, USA, Choose Size or package – 1.50″ cutting depth