Description

THE CLR MINIMUMS LISTED WITH MANDREL SIZES ARE GEOMETRIC MINIMUMS, AND DO NOT GUARENTEE PERFORMANCE OF ANY MATERIAL ON THE MINIMUM CLR. PLEASE CONSULT OUR TUBE CAPACITY CHART TO SEE MINIMUM WALL THICKNESS RATINGS FOR YOUR DESIRED CLR.

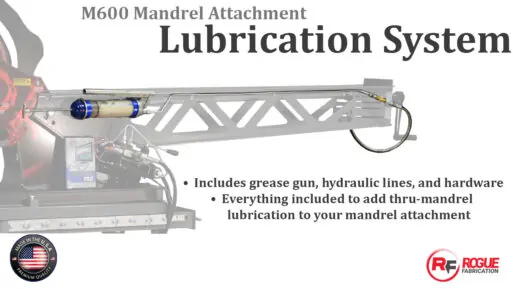

Mandrels for use in our M600 Mandrel Attachment. These are high performance CNC machined from nickel bronze alloy and feature ports for thru-mandrel lubrication injection for long mandrel life and further improved bending performance.

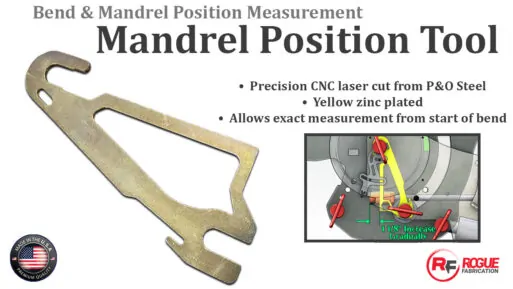

Since the mandrel supports the inside of the tubing being bent, it must be matched to the ID (inside diameter) of the tube. Tubing is usually sold and described as OD (Outside diameter) x wall thickness. That gives us the numbers to get tube ID, so we list our mandrels that way. The mandrels also have a tapered nose to support the tube just past the bend, which has to be matched to the bend radius. You can bend on a larger radius than your mandrel is tapered for, but not smaller. Here is an example:

You have a mandrel for 1.625 x .083 on 4.5 CLR. You can also use that mandrel on 1.625 x .083 on a 6.0 bend radius, but the nose of the mandrel will not touch the inside of the tube, only the cylindrical portion of the mandrel will. This will work, and it will vastly improve bends compared to no mandrel at all. It *may* not be as good as using the correct mandrel with the nose taper for the 6.0 CLR bend (this is true in extremely thin applications, but not common).

You can also use a mandrel on a tube with slightly larger ID than the mandrel is designed for, but no smaller. If the ID of the tube is a little larger than the mandrel was intended for, it will not fit as snug and will less control over the bend, resulting in higher deformation (but usually still MUCH less than not using a mandrel).

You may choose between a 1/2″ mandrel rod and a 3/4″ mandrel rod. The 3/4″ Mandrel rod covers applications down to 1 1/4″ OD tubing.

Common deformation in rotary draw bending is 5.5%-11% on moderate wall ratios. With mandrels set up properly, we have been seeing deformation in the range of 1.8-2.5%, which is extremely low!

We only have the mandrels that are in this product listing in stock. If you want another size (keep in mind wall ratios over 30 and bends tighter than 2.5D are not likely possible), please e mail us with your desired size (including CLR) and alloy. If this paragraph doesn’t make sense to you, click on “TECH” and then “BENDER TECH” above and read to learn more about these terms and tube bending in general.

1 review for Mandrels