Description

Patented under USPTO 11478838 with multiple other patents pending.

Current lead times: 1-2 weeks for Elite Packages containing benders, mandrel attachments, carts, and dies.

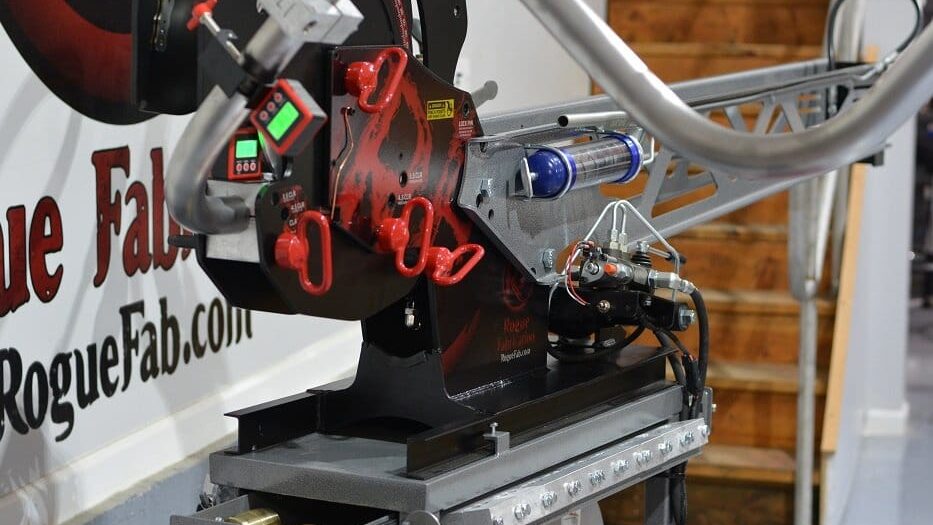

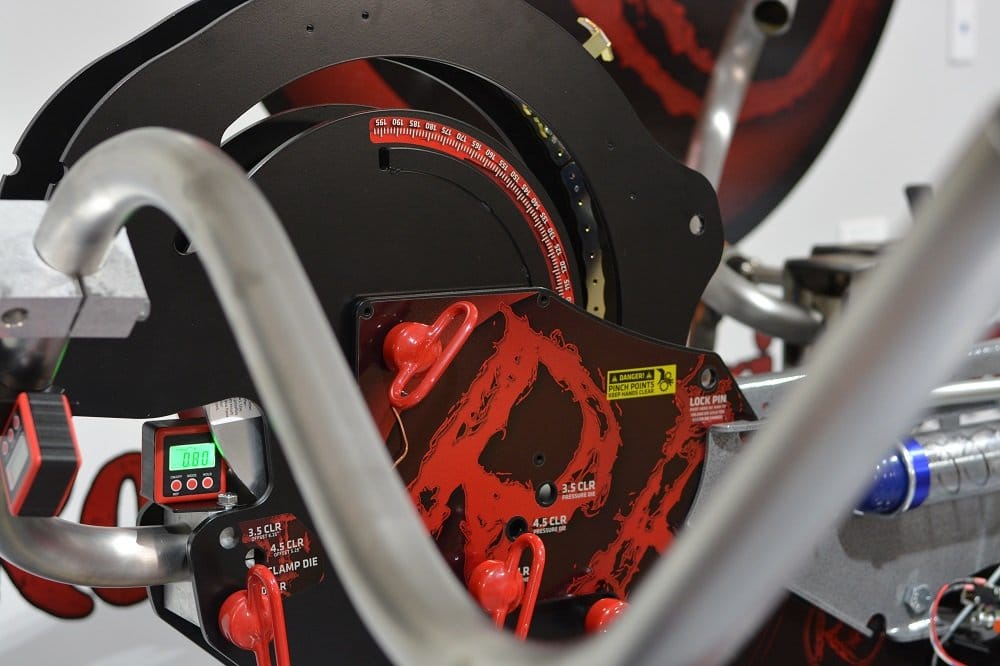

Our Elite Package is designed for serious fabrication shops that need a complete tube and chassis fabrication tooling package. This setup includes our broadest range of professional-grade tooling. You’ll receive our powder-coated Model 625 Tubing Bender with a premium vinyl wrap (featuring integrated machine operation instructions), all necessary hardware, and precision degree indicators. The complete setup rolls smoothly around your shop on our heavy-duty (1,000 lb capacity) steel cart, equipped with casters, two storage drawers, and four integrated die racks to keep everything organized and accessible.

M625 Warning: DuraPlates are pre-installed on all powder-coated frames and wheels. For weld-together kits, some minor reaming or cleanup of the 3/8″ holes may be required during assembly. Please note: DuraPlates are not automatically included with weld-together kits. Click here to add DuraPlates to your cart.

Dropdown Option 1: Tube Bender Model

All Elite Package configurations include our xHD M625 bender, welded and powder-coated.

This machine handles up to 2″ OD x .250″ wall steel, making it capable of tackling nearly anything you throw at it. The sleek vinyl wrap and stainless-steel Bender Upgrades Package ensure durability and aesthetics.

Dropdown Option 2: Die Package – 11 or 26 Dies?

The 11-die package includes the most popular sizes:

(Each listed as Outside Diameter × Centerline Radius – CLR)

-

2.00×6.00 HD

-

1.75×6.0 HD

-

1.625×6.0

-

1.50×6.0

-

1.50×6.0 square

-

1.25×4.5

-

1.25×4.5 square

-

1.00×3.5

-

1.00×4.5 square

-

0.875×3.5

-

0.750×3.5

If you prefer fractional sizes, this range covers from 3/4″ to 2″ in 1/4″ increments, plus 1-5/8″ and 7/8″, as well as 1″, 1-1/4″, and 1-1/2″ square sizes.

Each die includes double clamps for complex project use and comes with our new billet CNC die spacers.

Choosing the 26-die option adds:

-

0.500×3.5

-

0.500 square×3.5

-

0.625×3.5

-

0.625 square×3.5

-

1.375×4.5

-

1.50×4.5

-

1.75×4.5

-

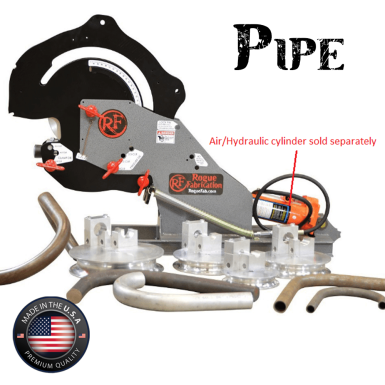

3/8″ pipe×3.5

-

1/2″ pipe×3.5

-

3/4″ pipe×4.5

-

1″ pipe×4.5

-

1-1/4″ pipe×4.5

-

1-1/4″ pipe×6.0

-

1-1/2″ pipe×6.0

-

1.25×6 HEX

This upgrade also includes a second Elite Cart with a top rack (where the bender typically mounts), giving you ample storage for all 25 dies across two carts.

Need help choosing a die? CLICK HERE

Want to see the capacity of every die? CLICK HERE

Dropdown Option 3: Add the Mandrel Package

Includes our M600 Mandrel Attachment with optional Thru-Mandrel Lubrication, a full set of mandrel accessories, and a selection of popular mandrels:

-

1″ × 0.049″

-

1.25″ × 0.049″

-

1.5″ × 0.065″, 0.070″, and 0.095″

-

1.625″ × 0.065″ and 0.083″

-

1.75″ × 0.083″ and 0.095″

-

2″ × 0.095″

Substitutions and custom sizes are available, you can find our full list of mandrel sizes HERE

More details on the Mandrel Attachment can be found HERE

Dropdown Option 4: Add the Shop Press Package with Tooling.

Choosing “Yes” adds our Shop Press Package, which includes:

-

Every dimple die we manufacture (round and shaped)

-

A gusset press frame

-

Three “taco dies”

Made in the USA.

More information about the shop press can be found on the product listing here

A video with more details on the capabilities of the VersaPress can be seen HERE

Machine Overview:

The RogueFab model 600 series is the best value tube bender on the market. Our bender is easy to use, accurate, and portable. We have the most affordable dies in the industry, and all of them bend 180+ degrees. You can forget about “90° one shot” benders that stop at 90. Our bender can do 94 degrees in one shot and then can continue and go past 180. Are you still looking at manual tubing benders? This modern machine was designed to run air/hydraulic or electric/hydraulic (ram is included in all elite packages). Compare our maximum capacity to the competition before you buy, because nothing else comes close. This machine can bend solid steel bars up to 2″ in diameter! We have the video to prove it. Click HERE to view our videos. Our bender can also make S-Bends, which is shown in our videos section. Lead Time Note: All components ship within the lead time listed at the top, except the Gusset Press Brake, which may take 1–4 weeks and can ship separately.

Our tube benders are built to grow with your shop.

Start strong with the M625 Extreme Heavy Duty bender and expand later:

-

Add a mandrel attachment for thin-wall tubing in steel, stainless, aluminum, or titanium

-

Upgrade to electric/hydraulic power with 9.5°/second speed and auto stops

-

Add a backstop and rotation gauges for precision 3D bends

-

Integrate with the best bending software in the industry (pre-configured for our machines)

Machine hydraulic power requirements:

-

1.5HP electric/hydraulic: ~8.1 amps @ 220–250V AC

-

2.0HP electric/hydraulic: ~12.5 amps @ 220–250V AC

-

Compatible with 60Hz or 208V power

-

Optional: 2HP system can be wired for 110V (pulls over 25A – not recommended)

Machine Dimensions:

M6xx tubing bender: (assembled, ready to bend): 12”x30” floor footprint. Overall dimensions 12”x47”x32” (LxWxH). Weight 140-200 lbs.

M6xx Bender on Cart: 22”x34” floor footprint. Overall dimensions 22”x47”x68” (LxWxH). Weight 210+ lbs (depends on cart contents).

M6xx Mandrel Bender on Cart: 22”x34” floor footprint. Overall dimensions 22”x105”x68” (LxWxH). Weight 295+ lbs (depends on cart contents).

Our web page is the single most complete source for information on tube bending. Read all of it in our Technical Index (LINK).

Check out a full project built with the M625!

Please read our terms and FAQ for complete information about warranty, returns, and more.

4 reviews for Complete Fabrication Shop ELITE Package